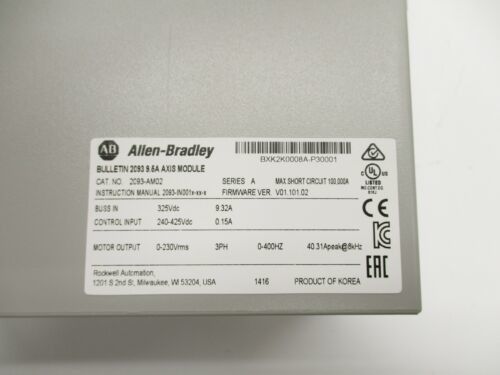

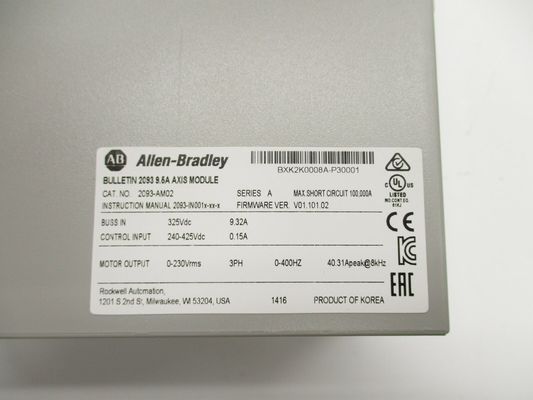

Product Description:2093-AM02

This servo motor is engineered to provide precise control of speed and position, making it suitable for a wide range of industrial automation tasks. It features a robust design that ensures reliable operation even in demanding environments. The 2093-AM02 integrates seamlessly with Kinetix drives, allowing for straightforward setup and enhanced motion capabilities.

The motor's synchronous operation allows for high torque output and efficient performance, which is crucial for applications requiring accuracy and responsiveness. Its compact design facilitates installation in tight spaces, while the compatibility with various feedback devices (like encoders) enhances positioning accuracy.

Overall, the 2093-AM02 is an excellent choice for applications in robotics, CNC machining, material handling, and other automation scenarios where precision and reliability are essential.

Features:2093-AM02

-

Synchronous Operation:

- Provides high torque and efficiency, enabling precise motion control suitable for dynamic applications.

-

Seamless Compatibility:

- Designed to integrate easily with Kinetix 6000 series servo drives, facilitating straightforward installation and configuration.

-

Feedback Device Support:

- Compatible with various feedback devices, such as encoders, enhancing positioning accuracy and control.

-

Compact Design:

- Space-efficient form factor allows for installation in tight spaces, optimizing system design.

-

Durability:

- Built to withstand harsh industrial environments, ensuring long-term reliability and performance.

-

Flexible Mounting Options:

- Offers various mounting configurations to accommodate specific application requirements.

-

Low Maintenance:

- Engineered for minimal maintenance needs, reducing downtime and operational costs.

-

High Performance:

- Delivers fast response times and consistent performance, making it suitable for a wide range of applications.

-

Wide Range of Applications:

- Ideal for robotics, CNC machinery, packaging equipment, material handling, and more.

-

Enhanced Safety Features:

- Incorporates safety features compliant with industry standards to ensure safe operation.

Technical Parameters:2093-AM02

Applications:2093-AM02

-

Control Parameter Tuning:

- Adjust settings such as acceleration, deceleration, and torque limits to tailor the motor’s response for specific tasks.

-

Feedback Device Selection:

- Choose from a variety of feedback devices (e.g., encoders) and configure them for precise positioning requirements.

-

Communication Integration:

- Customize communication settings to ensure compatibility with various control systems and protocols, such as Ethernet/IP.

-

Mounting Configurations:

- Adapt mounting options to fit unique installation requirements or constraints.

-

Motor Tuning:

- Perform advanced tuning to enhance performance characteristics, including responsiveness and stability.

-

Environmental Adaptations:

- Select protective enclosures or coatings to enhance durability in specific environmental conditions, such as moisture or dust.

-

Firmware Customization:

- Update or modify firmware to leverage new features or improve compatibility with other system components.

-

Performance Profiles:

- Create custom motion profiles that define specific operational sequences, speeds, and torque requirements.

-

Safety Function Configuration:

- Tailor safety parameters and functions to comply with industry regulations and specific operational safety needs.

-

Integration with Other Systems:

- Customize integration with other Rockwell Automation products or third-party devices for a cohesive automation solution.

Customization:2093-AM02

-

Control Parameter Adjustments:

- Fine-tune parameters such as acceleration, deceleration, and torque limits to optimize performance for specific applications.

-

Feedback Device Configuration:

- Select and configure various feedback devices (e.g., encoders) to ensure precise motion control and positioning accuracy.

-

Communication Protocol Settings:

- Customize settings for communication protocols, particularly for seamless integration with different control systems (e.g., Ethernet/IP).

-

Mounting Options:

- Adapt the motor’s mounting configuration to suit unique installation requirements or spatial constraints.

-

Motor Tuning:

- Perform motor tuning to enhance performance characteristics, such as responsiveness and stability, tailored to application demands.

-

Environmental Protection:

- Implement protective enclosures or coatings to ensure durability in specific environments, such as those with dust, moisture, or temperature extremes.

-

Firmware Updates:

- Regularly update or customize firmware to utilize new features or improve system compatibility.

-

Custom Motion Profiles:

- Develop and implement custom motion profiles to define specific operational sequences and performance requirements.

-

Safety Function Customization:

- Configure safety parameters to align with industry standards and specific operational safety needs, ensuring safe operation.

-

Integration with Existing Systems:

- Customize integration with other Rockwell Automation products or third-party devices to create a cohesive automation solution that meets specific operational requirements.

Support and Services:2093-AM02

Our team of expert technicians is available 24/7 to provide technical support and services for our Other product. Whether you need help with installation, troubleshooting, or maintenance, we are here to assist you every step of the way. Our services include:

- Remote technical support

- On-site repair and maintenance

- Software updates and upgrades

- Training and education

We are committed to providing our customers with the highest level of support and services to ensure that they get the most out of our Other product. Contact us today to learn more.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!