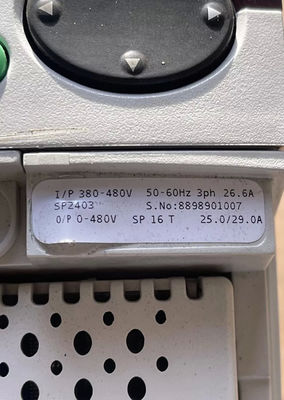

Product Description:SP2403

-

Modular Design: The SP2403 features a flexible, modular architecture that allows users to configure it based on their specific I/O requirements. It supports various I/O modules, communication protocols, and external devices for customized solutions.

-

High-Speed Control: Equipped with a powerful multi-core processor, the SP2403 is capable of executing control tasks in real-time with minimal delay, making it ideal for high-speed automation applications.

-

Scalability: The modular design allows for easy expansion, supporting additional I/O modules, communication interfaces, and redundant systems to grow with the application.

-

Robust Communication Support: The SP2403 PLC integrates seamlessly with other control systems and devices via Ethernet/IP, Modbus TCP/RTU, Profibus, DeviceNet, and CANopen protocols. It can also support wireless communication options for remote monitoring and control.

-

Redundancy and High Availability: For critical applications where uptime is essential, the SP2403 offers options for redundant CPUs and dual power supplies, ensuring continued operation even in the event of hardware failures.

-

Safety and Security: The SP2403 provides built-in security features such as user authentication, password protection, and encrypted communication for safe operation in secure industrial environments.

-

Web-Based Interface: The controller comes with an integrated web-based interface, allowing operators and engineers to access and monitor the system remotely through any standard web browser, facilitating easy diagnostics and troubleshooting.

-

Flexible Programming: Supporting IEC 61131-3 programming standards, the SP2403 allows users to develop control logic in various languages, including Ladder Logic, Structured Text, Function Block Diagram, and Sequential Function Chart. This makes it suitable for a wide range of automation applications.

-

Data Logging and Reporting: The PLC supports data logging, alarm management, and event recording, making it ideal for process monitoring and regulatory compliance in industries such as water treatment and manufacturing.

Features:SP2403

- Modular I/O System: Supports a wide variety of input/output modules, including digital, analog, and specialized I/O for flexible system configuration.

- Expandable: The system can easily be expanded by adding additional I/O modules, communication modules, or external devices, making it highly adaptable to different applications and needs.

- Multi-Core Processor: Equipped with a high-performance multi-core processor, providing fast processing power for real-time control applications.

- Fast Scan Times: The SP2403 can handle fast control tasks with minimal delays, making it ideal for time-critical applications such as motion control, machine automation, and process control.

- Ethernet/IP: Integrated Ethernet/IP support for high-speed communication with SCADA systems, HMIs, other PLCs, and remote I/O systems.

- Modbus TCP/RTU: Supports Modbus communication for connecting to a wide range of industrial devices and other control systems.

- Fieldbus Support: Includes protocols such as Profibus, DeviceNet, and CANopen for seamless integration with remote I/O, sensors, and actuators in industrial networks.

- Wireless Communication: Optional support for wireless communication (Wi-Fi, ZigBee) for remote monitoring and control, especially in hard-to-reach or mobile environments.

- Redundant CPUs: Optional redundant processors for high-availability applications, ensuring continued operation in case of a processor failure.

- Redundant Power Supplies: Dual power supply configuration available to ensure continuous operation and prevent downtime in critical applications.

- Hot-Swappable Modules: Allows users to replace I/O modules, power supplies, and communication modules without shutting down the system, enhancing uptime and reliability.

- User Authentication: Provides password protection and user-level access control to prevent unauthorized access to the PLC configuration.

- Data Encryption: Supports secure communication using TLS/SSL encryption to safeguard data exchanged over the network.

- Network Security: Includes firewall protection and intrusion detection systems (IDS) to protect against cyber threats and unauthorized network access.

- IEC 61131-3 Compliance: Supports IEC 61131-3 standard programming languages for flexibility and ease of integration into various control systems:

- Ladder Logic (LD): Widely used for traditional relay control.

- Structured Text (ST): For advanced mathematical functions and algorithms.

- Function Block Diagram (FBD): For process-oriented control logic.

- Sequential Function Chart (SFC): Ideal for sequence-based control systems.

- Instruction List (IL): Low-level programming support for legacy applications (though deprecated, still supported).

- ControlWave Designer Software: Emerson's proprietary ControlWave Designer software provides a user-friendly programming and configuration interface for easy setup and system integration.

- Data Logging: The SP2403 can log operational data, trends, alarms, and events, which can be exported for analysis or compliance reporting.

- Event and Alarm Management: Real-time monitoring of processes with the ability to trigger alarms or events based on predefined thresholds or conditions.

- Cloud Integration: Support for cloud-based data storage and analytics, enabling remote monitoring and access to historical data.

- Remote Access: Built-in web server for remote diagnostics, configuration, and monitoring via any standard web browser, allowing users to access and manage the system from anywhere.

- User-Friendly Interface: Provides real-time system information, performance data, and alarms through an intuitive graphical interface.

- Functional Safety (Optional): Can be configured to meet functional safety standards like IEC 61508 and IEC 61511, making it suitable for safety-critical applications in industries such as oil & gas and chemical processing.

- Watchdog Timer: Ensures continuous operation by monitoring the system and detecting issues or failures, triggering corrective actions when needed.

- Diagnostics and Troubleshooting: Built-in diagnostic tools and error reporting for easy troubleshooting, ensuring the system remains operational with minimal downtime.

- Low Power Consumption: Designed for efficient operation with low power consumption, making it ideal for energy-sensitive applications.

- Operating Temperature Range: Typically operates in environments with temperatures ranging from 0°C to 60°C (32°F to 140°F), ensuring reliable performance in most industrial environments.

- Wide Power Input Range: Typically operates with a 24V DC power input, with some flexibility for voltage tolerance.

- Compact Design: Space-efficient footprint suitable for installation in confined control panels or enclosures.

- Durability: Built to withstand harsh industrial environments, including dust, moisture, and electromagnetic interference (EMI), ensuring reliable performance in challenging conditions.

Technical Parameters:SP2403

- Type: Multi-core processor for high-speed, real-time control.

- Clock Speed: Approximately 1 GHz or higher, depending on configuration.

- Processing Power: High-performance architecture for handling complex control tasks with fast scan times.

- RAM: Typically 1 GB of volatile memory for program execution.

- Non-Volatile Storage: 512 MB to 1 GB of flash memory for storing programs, configuration files, and logs.

- External Storage: Supports USB ports or SD card slots for additional storage.

- Modular I/O: Expandable through various I/O modules (digital, analog, special-purpose modules).

- Digital I/O: Configurable from 16 to 64 digital inputs and outputs (per module).

- Analog I/O: Configurable 4 to 16 analog input/output channels (per module), with typical 12-bit or 16-bit resolution.

- High-Speed I/O: Capable of handling pulse counting and encoder feedback up to 100 kHz or higher.

- Relay Outputs: Supports high-power relay outputs for controlling devices like motors and actuators.

- Input Voltage: 24V DC (±10%).

- Power Consumption: Typically 30-50W (depending on I/O and communication modules).

- Redundant Power Supply: Available for increased system reliability.

- Ethernet/IP: Dual Ethernet ports for high-speed and redundant communication.

- Modbus TCP/RTU: Supported for integrating with industrial devices and networks.

- Profibus: Support for Profibus DP for device and I/O communication.

- DeviceNet: Communication support for devices in industrial networks.

- CANopen: Support for CAN bus systems, typically used in motion control and embedded applications.

- Serial Ports: Up to 4 RS-232/RS-485 ports for legacy device connections.

- Wireless Communication: Optional Wi-Fi or Zigbee support.

- Operating Temperature: Typically 0°C to 60°C (32°F to 140°F).

- Storage Temperature: -20°C to 85°C (-4°F to 185°F).

- Humidity: 5% to 95% relative humidity (non-condensing).

- Protection Rating: Typically IP20 for control modules (indoor use), with options for IP65/IP67 enclosures for rugged environments.

- Watchdog Timer: Integrated for monitoring system health and performance.

- Redundant CPU: Option for dual CPUs for failover and high availability.

- Hot-Swappable Modules: Allows replacement of components without system shutdown.

- IEC 61508 Compliance: Functional safety options for applications requiring safety standards.

- Programming Languages: Supports IEC 61131-3 programming standards (Ladder Logic, Structured Text, Function Block Diagram, Sequential Function Chart).

- ControlWave Designer: Emerson’s software for configuration, programming, and diagnostics.

- Control Module: Typically 120 mm to 200 mm (H) x 100 mm to 250 mm (W) x 120 mm to 180 mm (D).

- I/O Modules: Varies based on the I/O configuration, typically around 50 mm to 100 mm (W) x 120 mm to 150 mm (D).

- CE Mark: Conforms to European Union safety and environmental regulations.

- UL Certification: Approved for use in North America.

- RoHS Compliant: Free from hazardous substances per RoHS guidelines.

- CSA Certification: Suitable for Canada.

- Password Protection: Supports user authentication and access control.

- Encrypted Communication: Secure data transmission using TLS/SSL protocols.

- Intrusion Detection: Firewall and IDS features for cybersecurity.

Applications:SP2403

- Chemical Processing: Used to monitor and control critical parameters like pressure, temperature, flow, and chemical reactions. The SP2403 ensures consistent product quality and safety while maintaining efficiency.

- Oil & Gas: Essential for controlling operations in refineries, pipelines, and offshore platforms, managing flow meters, valves, pumps, and safety systems. It can be configured for high-availability operations and integrates easily with other equipment via communication protocols like Modbus and Profibus.

- Water and Wastewater Treatment: Controls pumps, valves, dosing systems, flow meters, and chemical dosing systems. It ensures consistent water quality by regulating filtration, chlorination, and pH levels.

- Pharmaceutical Manufacturing: Used in the pharmaceutical industry for precise control of batch processes, ensuring compliance with regulations like FDA 21 CFR Part 11 for data integrity and traceability.

- Automotive Manufacturing: Used to automate robotic arms, conveyors, and assembly lines for tasks like welding, painting, and parts assembly. The high-speed I/O and motion control capabilities make it ideal for fast-paced automotive production environments.

- Food & Beverage: Manages processing, packaging, and quality control in food and beverage production. The PLC can ensure consistent batch recipes, control temperatures, monitor equipment performance, and handle the integration of conveyors, mixers, and filling machines.

- Electronics and Consumer Goods: Automates production lines for assembling electronics, managing machines that place components, inspect products, and package finished goods. Its modular I/O allows for easy adaptation to different machine types.

- Packaging: Controls the operation of packaging machinery, such as labeling, filling, sealing, and palletizing, to ensure high throughput and consistency in packaging lines.

- Smart Grid: Used in smart grid systems to monitor and control energy distribution, manage power flow, and enable demand response. The PLC integrates with renewable energy sources, grid equipment, and energy meters to optimize grid efficiency.

- Power Generation: Manages operations in power plants, controlling turbines, generators, and auxiliary systems. It can monitor various parameters (temperature, pressure, vibration) to maintain optimal performance.

- Renewable Energy: In solar or wind farms, the SP2403 can regulate energy production, monitor the health of solar panels or wind turbines, and ensure efficient integration with the grid.

- Water Treatment & Distribution: In municipal water and wastewater systems, it controls pumps, filtration, chemical dosing, and storage tanks to ensure optimal water quality and distribution.

- HVAC Systems: Controls heating, ventilation, and air conditioning (HVAC) systems to maintain optimal building comfort, while minimizing energy consumption.

- Lighting Control: Manages lighting systems, including dimming, scheduling, and energy-efficient control, based on occupancy or time of day.

- Security and Access Control: Manages building security systems such as access control, alarm systems, and surveillance equipment, ensuring safety and compliance with regulations.

- Energy Management: Optimizes energy consumption in commercial buildings by controlling and monitoring electrical systems, lighting, HVAC, and other facilities. The SP2403 can reduce costs through demand-side management and energy optimization.

- Robotic Automation: Controls robotic arms, mobile robots, and autonomous vehicles in manufacturing, assembly, or material handling applications. It supports motion control tasks like speed control, positioning, and path tracking.

- Packaging Systems: Integrates with packaging machinery that requires precise positioning, synchronization of multiple actuators, and rapid decision-making for packing and palletizing products.

- Conveyor Systems: Controls high-speed conveyors, ensuring smooth and efficient transport of materials across production lines, while monitoring system performance and fault detection.

- CNC Machines: Used in computer numerical control (CNC) machines to automate the precise movement of tools, enhancing accuracy and productivity in machining processes.

- Textile Industry: Controls weaving, spinning, and dyeing processes in textile manufacturing, optimizing throughput while maintaining product quality.

- Mining: Monitors and controls critical equipment in mining operations, such as conveyor belts, crushers, and processing equipment, ensuring safe and efficient extraction of resources.

- Material Handling: Controls automated material handling systems in warehouses, shipping centers, and distribution facilities. It coordinates conveyors, sorting systems, and robotic arms to ensure smooth logistics operations.

- Emergency Shutdown (ESD): Used in chemical plants, refineries, and other hazardous environments to trigger emergency shutdown sequences in case of system anomalies or safety breaches, ensuring worker safety and environmental protection.

- Safety Instrumented Systems (SIS): Can be part of a larger SIS, performing critical safety functions like overpressure protection, fire detection, or gas leak detection.

The SP2403 PLC provides data acquisition and monitoring capabilities for industries that require constant supervision and data logging:

- Industrial Data Logging: Logs operational data for process control and quality assurance. This includes temperature, pressure, flow rates, and other sensor outputs, which can be stored for analysis and troubleshooting.

- Remote Monitoring: Supports cloud-based monitoring and control, allowing operators and engineers to monitor the system remotely for performance data, troubleshooting, and diagnostics.

The SP2403 can be used for environmental monitoring in industrial applications to control systems that require regulatory compliance and continuous performance checks:

- Air Quality Control: In factories and industrial plants, it monitors emissions, particle levels, or CO2, ensuring compliance with environmental regulations.

- Temperature and Humidity Control: Used in controlled environments such as server rooms, pharmaceutical storage, or food storage to monitor and regulate conditions.

Customization:SP2403

-

Customizable I/O Modules: The SP2403 supports a wide range of digital and analog I/O modules, allowing users to choose the precise number and type of inputs/outputs required for their application. This includes:

- Digital Inputs and Outputs: For controlling on/off devices such as switches, sensors, and relays.

- Analog Inputs and Outputs: For handling continuous signals like temperature, pressure, and flow rate from sensors or controlling actuators like valves and pumps.

- Special-Purpose I/O Modules: Custom I/O modules for specific needs like high-speed pulse counting, encoder feedback, or motion control.

-

Custom I/O Expansion: The I/O system is scalable and can be expanded by adding additional modules, providing the flexibility to adjust the system size as the application grows or changes.

- Communication Module Customization: The SP2403 can be configured with a variety of communication modules, allowing integration with diverse industrial networks and systems:

- Ethernet/IP, Modbus TCP/RTU for standard industrial communication.

- Profibus, DeviceNet, CANopen, and Modbus RTU for legacy or specialized communication with field devices.

- Wireless Communication: Optional wireless modules for remote connectivity via Wi-Fi, Zigbee, or other wireless standards.

- Custom Protocol Integration: Emerson's ControlWave Designer software provides the ability to configure custom communication protocols and integrate with third-party devices or other control systems, making the SP2403 adaptable to a wide range of industrial environments.

-

Redundant CPUs: For applications where system uptime is critical, the SP2403 offers the option of redundant CPUs, ensuring high availability and failover capabilities in case of a hardware failure.

-

Dual Power Supplies: The PLC supports redundant power supplies for critical applications, ensuring continuous operation even in the event of a power supply failure.

-

Hot-Swappable Modules: I/O and communication modules can be replaced without shutting down the system, providing high availability for mission-critical processes.

- Multiple Programming Languages: The SP2403 adheres to IEC 61131-3 programming standards, which allow for programming in various languages to suit different user preferences and application requirements:

- Ladder Logic (LD): Traditional relay-based logic, widely used in control systems.

- Structured Text (ST): For complex mathematical and logical operations.

- Function Block Diagram (FBD): Ideal for process-oriented applications.

- Sequential Function Chart (SFC): Used for sequential control in batch processes.

- Custom Function Blocks: Users can create custom function blocks (FBs) for specific control logic or processing tasks, enabling highly tailored control strategies.

-

Web-Based Interface: The SP2403 comes with an integrated web-based interface that can be customized to allow operators to monitor and control the system remotely. Through a standard web browser, users can:

- Access system diagnostics, performance metrics, and alarm information.

- Modify parameters and configurations in real time.

- Customize dashboards and views to suit user needs.

-

HMI Integration: The SP2403 can also be integrated with third-party Human-Machine Interface (HMI) systems for a more visual control and monitoring experience. Custom screens, data display, and operator interactions can be designed to match the specific layout and operational needs of the facility.

-

Customizable Data Logging: The SP2403 allows users to configure data logging for different variables and parameters, enabling customized logging intervals, data storage locations, and formats. This can be used for:

- Process optimization.

- Regulatory compliance (e.g., recording temperature or flow data in pharmaceutical or food production).

- Performance analysis and predictive maintenance.

-

Alarm and Event Management: Customizable alarm thresholds, event triggers, and notification settings can be set based on specific operational parameters, ensuring timely alerts for operators when conditions fall outside acceptable ranges.

-

High-Precision Motion Control: The SP2403 supports advanced motion control, including positioning, velocity control, and synchronization of multiple axes. This is crucial for applications such as robotics, packaging, and CNC machines.

-

Custom Motion Profiles: The controller can be programmed to handle custom motion profiles, enabling fine control over speed, acceleration, and deceleration, along with real-time feedback from encoders and other motion sensors.

-

Functional Safety Integration: The SP2403 can be customized for functional safety applications to meet safety standards like IEC 61508, IEC 61511, and SIL (Safety Integrity Level) requirements. This can include:

- Emergency shutdown (ESD).

- Safety instrumented systems (SIS).

- Redundant safety I/O.

-

Custom Safety Logic: Safety logic can be tailored to the specific needs of the application, providing a configurable approach to handling emergency situations or process deviations.

-

Cloud-Based Analytics: The SP2403 can be integrated with cloud-based platforms to enable remote monitoring, data analytics, and control. Data from the PLC can be sent to the cloud for advanced analytics, condition monitoring, or optimization strategies.

-

Remote Diagnostics: Custom remote diagnostics can be set up to monitor system health, send alerts, and allow for troubleshooting without the need to be physically present at the facility.

- Custom Enclosures: The SP2403 PLC modules and controllers can be installed in custom enclosures to meet the environmental conditions of the installation location. This includes:

- IP65 or IP67-rated enclosures for dusty or wet environments.

- Explosion-proof enclosures for hazardous environments such as chemical plants or oil rigs.

- Temperature and Humidity Range Customization: The system can be adapted to work within specific temperature and humidity ranges, making it suitable for both extreme and controlled environments.

- Custom Reports: Users can define the format, frequency, and content of reports generated by the SP2403. Reports can include system status, process data, alarms, and compliance documentation.

- Audit Trails: Customized audit trails for tracking user activities, system changes, and error logs for compliance purposes, particularly in regulated industries like pharmaceuticals or food production.

Support and Services:SP2403

Our product technical support team is available to provide assistance with any questions or issues you may have regarding the Other product. Our knowledgeable technicians are trained to troubleshoot and resolve a wide range of technical issues, including software and hardware problems, connectivity issues, and more.

We also offer a range of services to help you get the most out of your Other product, including installation and setup support, product training, and customization services. Our goal is to ensure that you have a positive experience with our product and that you are able to use it to its fullest potential.

If you require technical support or any of our services, please don't hesitate to contact us. Our support team is available to assist you via phone, email, or live chat.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!