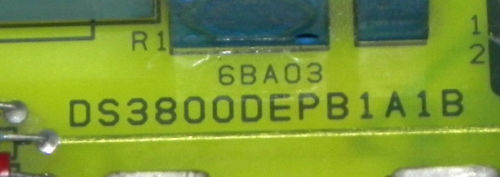

Product Description:DS3800DEPB

It is built on a printed circuit board (PCB) with a carefully designed layout. The PCB likely has multiple layers to efficiently route power, ground, and signal lines while minimizing electrical interference between different components. The layout is optimized for easy integration with other boards or modules within the overall system.

- 20-Pin Ribbon Cable Connector: The presence of a 20-pin ribbon cable connector indicates its ability to interface with other components in a specific way. This connector is likely used for transmitting a combination of power, control signals, or data between the DS3800DEPB and other parts of the system. It provides a standardized and reliable means of connection, allowing for easy installation and replacement if needed.

- Five 10-Pin Connectors: The five 10-pin connectors on the board serve different purposes. They are probably used to connect to various sensors, actuators, or other circuit boards in the system. These connectors can handle different types of signals, including digital and analog signals, enabling the DS3800DEPB to communicate with a wide range of external devices. For example, some of these connectors might be used to interface with temperature sensors, pressure sensors, or motor control circuits.

- Four Terminals for Adding Components: The four terminals provided on the board offer the possibility of adding additional components. This allows for a certain degree of customization and expansion of the board's functionality. Users can, for instance, add capacitors, resistors, or other discrete components to meet specific application requirements. However, such modifications usually require technical expertise and proper calibration to ensure that the added components do not disrupt the normal operation of the board or the overall system.

- Two Trimpotentiometers: The two trimpotentiometers on the board are adjustable components that can be used to fine-tune certain electrical parameters. They might be used to calibrate voltage levels, set signal thresholds, or adjust gain values for analog signals. This provides flexibility in configuring the board to match the specific input and output requirements of the industrial process it is involved in.

Features:DS3800DEPB

-

The DS3800DEPB is likely involved in power supply functions within the system. It may receive a primary power input from an external source, which could be a standard industrial voltage such as 24VDC or 120/240VAC, depending on the specific application. The board then distributes this power to different parts of the circuit and potentially to connected external devices through its various connectors. It may incorporate power regulation and filtering circuits to ensure a stable and clean power supply, protecting sensitive components from voltage fluctuations and electrical noise.

- Analog Signal Handling: The board is capable of handling analog signals received from sensors or other sources. It can perform functions like amplification, filtering, and analog-to-digital conversion (ADC). For example, if it receives an analog voltage signal from a temperature sensor that represents the temperature of a critical component in a power generation turbine, it can amplify the weak signal to a suitable level for further processing, filter out any noise or interference, and then convert it into a digital value that can be processed by the system's control algorithms.

- Digital Signal Handling: It also deals with digital signals, which could include signals from switches, relays, or digital communication interfaces. The DS3800DEPB can perform operations such as signal conditioning (ensuring proper voltage levels and logic states), buffering to drive external loads, and decoding or encoding of digital data for communication purposes. For instance, it can receive a digital signal indicating the status of a safety switch and process it to trigger appropriate actions in the control system, like shutting down a motor or activating an alarm.

The multiple connectors on the board enable it to communicate with a variety of other components in the system. It can exchange data and control signals with other circuit boards, Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), or other monitoring and control devices. This communication can be based on different protocols, depending on the specific design and application. It might support serial communication protocols like RS-232 or RS-485 for connecting to legacy or specialized devices, as well as Ethernet-based protocols for integration with modern networked systems. This multi-protocol support enhances its compatibility and flexibility in different industrial setups.

Overheating Protection: The DS3800DEPB is equipped with mechanisms to protect itself from overheating. It likely has temperature sensors or thermal protection circuits that can detect when the internal temperature of the board exceeds a safe threshold. In case of overheating, it can trigger actions such as reducing power consumption, shutting down certain functions, or sending an alert to the system's monitoring interface. This helps prevent damage to the board and ensures its long-term reliability in often hot industrial environments.

Overcurrent Protection: To safeguard against excessive current flow, which could damage components on the board or connected devices, it incorporates overcurrent protection features. These might include fuses, current-limiting circuits, or electronic protection modules that can detect when the current exceeds a predefined limit and take appropriate measures, such as interrupting the power supply or reducing the load to avoid component failure..

Technical Parameters:

The DS3800DEPB is mainly designed for use in industrial settings, particularly in applications related to power generation, such as gas turbine control systems. In a gas turbine power plant, it can be part of the control loop that monitors and controls various parameters of the turbine, including temperature, pressure, and rotational speed. It interfaces with sensors located throughout the turbine system to gather real-time data and sends control signals to actuators like fuel injectors, valves, and cooling fans to optimize the turbine's performance and ensure its safe operation.

It is designed to integrate seamlessly with other components of the overall industrial control system. It can be mounted in a control cabinet alongside other circuit boards, PLCs, and power supplies. The standardized connectors and compatibility with common communication protocols allow for easy connection and configuration within the system. Additionally, its ability to have additional components added through the terminals provides flexibility for adapting to specific system requirements or for making upgrades or modifications as the industrial process evolves over time.

The RELIANCE 1C1227G01 SIRIUS Safety Relay Basic Unit with time delay is an advanced series safety relay that is suitable for various applications. This product has an installation altitude at a height above sea level maximum of 2000mm and has a protection class IP of the enclosure of IP20. The insulation voltage rated value is Relative Humidity During Operation, and it has a degree of pollution of 3. The product is made in America and comes in a carton for packaging.

The RELIANCE 1C1227G01 SIRIUS Safety Relay Basic Unit with time delay has a spring-type terminal with push-in installation. It has two NO instantaneous and two NO delayed relay enabling circuits that make it suitable for a wide range of applications. The product is designed to be used with a Us of 24 V DC.

This product can be used in various scenarios, such as battery management systems, industrial automation, and control systems. The RELIANCE 1C1227G01 SIRIUS Safety Relay Basic Unit can be used to control the charging and discharging of batteries in battery management systems. It can also be used in industrial automation to control the operation of machines and equipment. Additionally, the product can be used in control systems to control the operation of various components in a system.

The RELIANCE 1C1227G01 SIRIUS Safety Relay Basic Unit with time delay is suitable for use in various applications and industries. Its advanced features and reliable performance make it an ideal choice for industrial automation and control systems. The product is certified and has a minimum order quantity of one unit. The delivery time for this product is 6-8 weeks, and the payment terms are T/T. The supply ability for this product is one unit.

Customization:DS3800DEPB

The four terminals provided on the DS3800DEPB board allow for the addition of extra components such as capacitors, resistors, or other discrete electrical elements. For example:

- Capacitor Addition for Power Conditioning: In an industrial environment where there are significant power fluctuations or electrical noise issues, additional capacitors can be added to improve the power supply filtering on the board. By carefully selecting the capacitance value and connecting the capacitors to the appropriate terminals, users can enhance the stability of the power provided to different parts of the circuit. This can be particularly useful in applications like a power generation plant where other heavy machinery might cause electrical disturbances that could affect the sensitive components on the DS3800DEPB.

- Resistor Inclusion for Signal Adjustment: Depending on the specific sensors or actuators connected to the board, resistors can be added to adjust signal levels. For instance, if a particular analog sensor has an output signal that needs to be attenuated or amplified to match the input range requirements of the board's analog input channels, the right resistors can be connected to the terminals to create a voltage divider or amplification circuit. This enables precise signal conditioning for accurate data processing.

Once additional components are added, proper configuration and calibration are essential. This requires technical expertise and the use of appropriate calibration tools. For example:

- Using Calibration Testers: After adding components, a calibration tester can be used to measure and adjust electrical parameters. If capacitors are added for power factor correction, the tester can measure the capacitance value and ensure it is within the desired range to achieve the intended improvement in power quality. Similarly, for resistors used in signal conditioning, the tester can verify the resistance value and make any necessary adjustments to ensure accurate signal processing. The calibration process might involve fine-tuning the component values based on the specific performance requirements of the system and the characteristics of the connected devices.

- Evaluating Impact on Overall System: It's crucial to assess how the added components affect the overall operation of the DS3800DEPB and the larger industrial control system. For example, adding a capacitor might change the power consumption profile of the board, which could impact other components sharing the same power supply or trigger certain power management features. Users need to monitor and analyze parameters such as voltage stability across different parts of the circuit, signal integrity of both analog and digital signals, and the performance of connected actuators and sensors to ensure that the customization has a positive impact and doesn't introduce any new issues.

The two trimpotentiometers on the board offer the ability to fine-tune various analog signal-related parameters. For example:

- Voltage Level Calibration: In a temperature monitoring application where an analog temperature sensor is connected to the board, the trimpotentiometer can be adjusted to calibrate the voltage range corresponding to different temperature values. If the sensor's output voltage range needs to be adjusted to match the expected input range of the board's analog-to-digital conversion (ADC) channels, the trimpotentiometer can be used to set the appropriate voltage offset or gain. This ensures that the temperature readings obtained by the system are accurate and consistent.

- Signal Threshold Setting: In a control system where certain actions are triggered based on analog signal levels, such as opening or closing a valve when a pressure sensor reaches a specific pressure threshold, the trimpotentiometer can be used to precisely set that threshold. By adjusting it, users can define the exact point at which the system responds to changes in the analog input signal, allowing for customized control logic based on the specific requirements of the industrial process.

While trimpotentiometers are mainly associated with analog signals, in some situations, they can also have an impact on digital signal characteristics indirectly. For example:

- Logic Level Adjustment for Compatibility: In a system where the DS3800DEPB needs to interface with different types of digital devices that have slightly varying logic level requirements, the trimpotentiometer can be used to adjust the output voltage levels of digital signals from the board. This ensures proper compatibility and reliable communication between the board and the connected digital devices. Although this might not be the primary function of the trimpotentiometers, it provides an additional level of customization in certain integration scenarios.

- Ethernet Protocol Customization: Depending on the network infrastructure and the other devices present in the industrial setup, users can choose to enable or disable specific Ethernet-based protocols on the DS3800DEPB. For example, if the plant has a mix of devices that support both TCP/IP and Modbus/TCP, the user can configure the device to communicate using the most suitable protocol for each connection. The IP address, subnet mask, and default gateway can also be customized. In a large industrial facility with multiple subnets, the device can be assigned an IP address within the appropriate subnet to ensure seamless communication with other devices in that network segment.

- Serial Protocol Customization: For serial communication, users can select between RS-232 and RS-485 protocols based on the requirements of the connected devices. If there are legacy devices that only communicate via RS-232, the DS3800DEPB can be configured to use this protocol. The baud rate, data bits, stop bits, and parity settings for both RS-232 and RS-485 can be modified. For instance, when connecting to a sensor that requires a specific baud rate for accurate data transmission, the user can set the appropriate baud rate on the device's serial interface to ensure reliable communication.

- Selective Data Transmission: Users can define which specific data fields are sent or received during communication. In a power generation plant where numerous sensors are collecting data on various turbine parameters, the user can configure the DS3800DEPB to transmit only the most critical data, such as turbine speed, exhaust temperature, and fuel flow rate, to the central monitoring system at specific intervals. This reduces network traffic while still providing essential information for effective monitoring and decision-making.

- Adjusting Data Transmission Frequency: The frequency of data transmission can be customized based on the rate of change of the data and the monitoring requirements. For example, in a relatively stable power generation process where some parameters like turbine bearing temperature change slowly, the device can be set to send updates less frequently, perhaps every 10 minutes. In contrast, in a situation where rapid changes need to be monitored closely, like the combustion conditions within the turbine, the device can be configured to transmit data at a very high frequency, such as several times per second.

- Data Encoding and Formatting: The device can be programmed to package data in a specific format that is compatible with the receiving system. For instance, data can be formatted as JSON (JavaScript Object Notation) or XML (Extensible Markup Language) depending on the requirements of the software used for data analysis, storage, or visualization in the industrial network. This ensures seamless integration and easy processing of the data by other systems in the network.

- Input Voltage Threshold Adjustment: The input voltage thresholds for digital input ports can be adjusted to match the output characteristics of different types of digital sensors. In an industrial automation setup with a variety of proximity sensors having different voltage levels for indicating the presence or absence of an object, the user can configure the input thresholds on the DS3800DEPB to accurately detect the signals from each sensor. For example, if a particular sensor outputs a logic high signal at a voltage slightly lower than the default threshold, the threshold can be lowered to ensure proper recognition of the sensor's output.

- Output Voltage and Current Level Modification: The output voltage and current levels of digital output ports can be customized to drive specific load devices more effectively. If a motor requires a higher starting current than the default output of the device can provide, the current limit can be increased (within the device's capabilities) by adjusting relevant settings. Similarly, if an indicator light needs a different voltage level for proper illumination, the output voltage can be adjusted accordingly to ensure it functions as intended.

- Function Repurposing of Digital I/O Ports: The functionality of digital I/O ports can be repurposed based on the application requirements. For example, a digital input port that was initially intended to monitor a switch can be configured to receive a pulsed signal from a different device for a specific timing or counting function. Or a digital output port that was used to control a small motor can be set to drive a relay for a different electrical circuit depending on the evolving needs of the industrial process.

- Input Signal Range Adjustment: The voltage or current ranges for analog input channels can be set according to the output range of the connected sensors. In a temperature monitoring application where a custom-designed temperature sensor has an output voltage range different from the standard -10V to +10V, the analog input range on the DS3800DEPB can be adjusted to match that specific sensor's output. This allows for accurate conversion of the sensor's signal into a digital value for processing.

- Resolution Customization: The resolution of the analog input channels can be customized to balance the need for precision and data processing requirements. In a process where extremely accurate measurements are not essential but a higher sampling rate is preferred to capture rapid changes, the resolution can be decreased to free up processing resources and increase the sampling frequency. Conversely, in a situation where precise measurements are crucial (like in a pharmaceutical formulation process), the resolution can be increased to obtain more detailed data.

- Output Signal Range and Accuracy Calibration: The output signal range and accuracy of the analog output channels can be calibrated and adjusted for specific actuators. For example, if a valve actuator requires a very precise control signal within a narrow voltage range to achieve accurate positioning, the analog output range and accuracy settings of the device can be fine-tuned to meet those requirements. This ensures that the actuator responds as expected and enables precise control of industrial processes.

Support and Services:DS3800DEPB

Our technical support team is available to assist you with any questions or concerns you may have regarding our Other product. We offer a range of support services, including:

- Phone support during business hours

- Email support 24/7

- Online knowledge base with articles and FAQs

- Product documentation and user guides

- Remote troubleshooting and diagnostics

In addition to our technical support services, we also offer product training and consulting services to help you get the most out of your Other product. Our team of experts can provide customized training programs and consulting services tailored to your specific needs and business objectives.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!