Product Description:DS3800DMPC

- Central Control and Coordination: At the heart of its functionality, the DS3800DMPC acts as the brain of the Mark IV turbine management system. It is responsible for executing a wide variety of control algorithms and logic to manage the operation of the turbine. This includes controlling parameters such as turbine speed, load, temperature, and pressure, ensuring that the turbine operates within safe and optimal operating conditions. For example, it can adjust the fuel supply to a gas turbine or the steam flow to a steam turbine based on the current load demand and other operating parameters to maintain stable power generation or mechanical drive output.

- Data Processing and Monitoring: The board continuously processes a vast amount of data received from various sensors located throughout the turbine system. These sensors measure parameters like temperatures at different points in the turbine, pressures in the steam or gas lines, rotational speeds, and vibration levels. The DS3800DMPC analyzes this data to assess the health and performance of the turbine. It can detect any abnormal trends or deviations from normal operating conditions, enabling timely responses to potential issues and facilitating preventive maintenance.

- Communication and Integration: It serves as a communication hub within the turbine management system, interfacing with other control boards, I/O (input/output) modules, and external monitoring and control systems. Through its communication interfaces, it exchanges data with components such as actuator control boards that manage the positioning of valves and other mechanical actuators in the turbine system. It also connects with higher-level plant control systems or SCADA (Supervisory Control and Data Acquisition) systems to provide real-time status updates and receive operating instructions, ensuring seamless integration of the turbine into the overall industrial process.

- Fault Tolerance and Redundancy Support: Given its role in critical turbine operations, the DS3800DMPC is designed to support the triple-module-redundancy (TMR) architecture of the Mark IV system. In this setup, multiple instances of the board (or similar modules) operate simultaneously, and their outputs are compared through a voting mechanism. This allows the system to identify and correct errors or continue operating even if one of the modules fails. By providing this level of fault tolerance, it helps ensure the reliability and continuous operation of the turbine, minimizing downtime and protecting against costly disruptions in power generation or industrial processes.

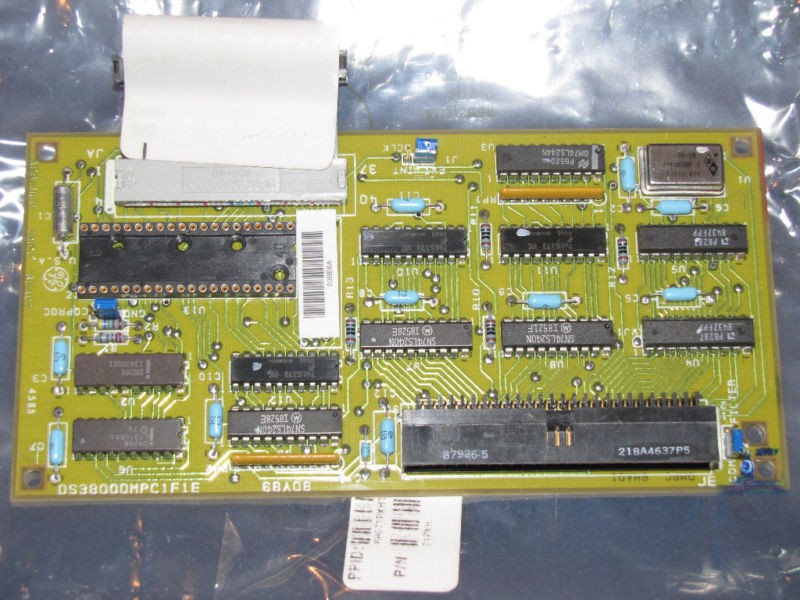

- Physical Design: The DS3800DMPC has a distinct physical layout and form factor. It is a relatively small circuit board with a design that optimizes space utilization while accommodating its various components. The board has holes drilled at each corner, which are likely used for mounting purposes within the equipment enclosure. Its surface is marked with the GE logo and specific codes like "c-ess," which help in identification and proper installation. The unique design with the top layer cut away at the corners to expose the bottom layer might serve purposes related to electrical connections, heat dissipation, or component access.

- Component Quality: Incorporating high-quality electronic components is a key aspect of its design. The use of components such as precision metal film resistors, polyester vinyl and ceramic capacitors, and multiple integrated circuits, including oscillator chips, ensures stable and accurate performance. These components are carefully selected for their ability to withstand the electrical, thermal, and mechanical stressors typical of industrial turbine environments. They are sourced and assembled with strict quality control measures to guarantee reliable operation over an extended lifespan.

- Circuitry and Electronics: The internal circuitry of the board is complex and highly specialized. The resistor network arrays are configured to provide specific resistance values that are crucial for setting up voltage dividers, current-limiting circuits, or other electrical functions within the control logic. The capacitors perform functions like filtering out electrical noise from power supplies and signals, as well as coupling signals between different stages of the circuits. The integrated circuits, with their diverse functions, work together to implement the microprocessor's core capabilities, including data processing, instruction execution, and generation of control signals for the turbine system. The jumper switches add an element of flexibility, allowing for customization of the board's functionality by changing the electrical paths and enabling or disabling certain features based on the specific requirements of the turbine installation.

- Microprocessor Technology: The DS3800DMPC relies on microprocessor technology to carry out its control and data processing tasks. The microprocessor on the board likely has a specific instruction set and processing power designed to handle the real-time demands of turbine control. It can execute complex algorithms related to control loops (such as PID control for regulating turbine speed or temperature), handle interrupts from sensors or other components, and manage communication protocols for seamless interaction with other parts of the system.

- Redundancy and Voting Technologies: As part of the TMR architecture, it employs specific redundancy and voting technologies. This involves the use of multiple identical or similar modules running in parallel and a voting mechanism (which could be implemented in hardware or software) to compare their outputs. Based on the voting results, the system can determine the correct output and take appropriate action in case of discrepancies, ensuring the integrity of the control signals and the overall reliability of the turbine management system.

Features:DS3800DMPC

- Powerful Processing Capability: It is equipped with a microprocessor that has sufficient processing power to handle complex control algorithms and manage a large volume of data in real-time. This enables it to execute tasks such as calculating optimal turbine operating parameters based on various inputs (like load demand, sensor readings), coordinating multiple control loops simultaneously, and making quick decisions to adjust the turbine's operation. For example, it can rapidly compute the appropriate fuel injection or steam flow adjustments in response to changes in power generation requirements or system disturbances.

- Real-Time Operation: The microprocessor on the DS3800DMPC is designed for real-time operation, meaning it can respond promptly to events and changes in the turbine system. Whether it's a sudden change in load, a fluctuation in inlet conditions (e.g., gas pressure or steam temperature), or a sensor detecting an abnormal condition, the board can immediately take action to maintain stable and safe turbine operation. This real-time responsiveness is crucial for preventing issues like turbine overspeed, overheating, or sudden power drops.

Quality Components: Built with high-quality electronic components, including precision resistors, capacitors, and integrated circuits, it is designed to withstand the harsh conditions typical of industrial turbine environments. These components are selected for their ability to handle high temperatures, electrical stress, vibration, and long-term operation without significant degradation. This ensures a long lifespan and reliable performance of the DS3800DMPC, reducing the frequency of component replacements and maintenance requirements.

Environmental Resilience: The board is likely engineered to be resistant to environmental factors such as dust, moisture, and electromagnetic interference. It may have features like conformal coatings to protect against moisture and dust ingress, and proper shielding to minimize the impact of external electromagnetic fields. This enables it to operate reliably in various industrial settings, from power plants located in different climates to refineries and chemical plants with potentially harsh operating conditions.

Multiple Protocol Support: The board is equipped with communication interfaces that support various protocols, facilitating seamless integration with other components in the turbine management system and with external systems. It can communicate using standard industrial protocols like Modbus (for connecting with I/O modules, sensors, or other control devices) as well as GE's own proprietary protocols for integration with other GE equipment in the Mark IV system. This enables efficient data exchange and coordinated control among different parts of the turbine installation and with higher-level plant control systems.

Interconnectivity: The DS3800DMPC has connectors, such as the right-angle cable connector and the ribbon connector, which allow it to connect with adjacent control boards, sensors, actuators, and other elements of the turbine system. This interconnectivity ensures smooth flow of information and control signals throughout the system, enabling the board to play its central role in coordinating the overall operation of the turbine.

Triple Module Redundancy (TMR) Compatibility: The DS3800DMPC is designed to work within the TMR architecture of the Mark IV system. This means that multiple copies of the board can operate simultaneously, and their outputs are compared through a voting mechanism. In case one of the modules malfunctions or provides incorrect data, the voting process ensures that the correct control signals are sent to the turbine, maintaining its stable operation. This redundancy significantly enhances the reliability of the turbine management system, especially in critical applications where downtime can have severe consequences, such as in power plants supplying electricity to a large grid.

Error Detection and Recovery: It has built-in error detection capabilities to identify issues within the board itself or in the data it processes. When an error is detected, it can trigger appropriate recovery actions, such as attempting to correct the issue through internal self-correction mechanisms (if possible), alerting the system operator, or initiating a graceful shutdown or transition to a backup mode to protect the turbine from damage.

Jumper Switch Customization: The presence of jumper switches on the board provides a significant level of flexibility in configuring its functionality. Operators or system integrators can change the position of these jumpers to alter the electrical connections and enable or disable specific features or control paths. This allows for tailoring the DS3800DMPC to the unique requirements of different turbine models, operating conditions, or specific industrial processes. For example, a particular jumper configuration might be used to switch between different control modes depending on whether the turbine is operating in a base load or peaking power generation scenario.

Programmable Settings: It likely offers programmable settings through its software or firmware. Users can adjust parameters such as control loop gains, setpoint values for various turbine parameters (like target speed, temperature limits), and communication settings. This programmability enables fine-tuning of the turbine control to achieve optimal performance and adapt to changing operational needs over time.

Comprehensive Data Handling: It has the ability to process data from a wide range of sensors located throughout the turbine system. This includes temperature sensors (monitoring component temperatures like turbine blades, bearings, etc.), pressure sensors (in steam or gas lines), rotational speed sensors, and vibration sensors. By integrating and analyzing this diverse data, it can build a comprehensive picture of the turbine's health and performance, enabling precise control and early detection of potential problems.

Data Analytics and Trending: The board likely incorporates features for data analytics and trending. It can identify patterns in the sensor data over time, such as gradual changes in temperature trends that might indicate component wear or a developing issue. This allows operators and maintenance teams to predict maintenance needs, optimize turbine performance, and take proactive measures to avoid costly breakdowns. For instance, it can detect if a particular bearing is starting to run hotter than normal over several hours or days and alert the relevant personnel before a failure occurs.

Technical Parameters:DS3800DMPC

-

- It likely has a specific range of acceptable input voltages to power its internal circuits. This could be something like 110 - 240 VAC (alternating current) for compatibility with standard industrial power supplies, or perhaps a DC (direct current) input voltage range in the order of 24 - 48 VDC depending on its design and the power source available in the turbine management system. The voltage tolerance around these nominal values would typically be defined to account for minor fluctuations in the power source. For example, it might have a tolerance of ±10% around the nominal AC voltage, meaning it can operate reliably within a range of approximately 99 - 264 VAC.

- Input Current Rating:

- There would be an input current rating that indicates the maximum amount of current the device can draw under normal operating conditions. This helps in sizing the appropriate power supply and circuit protection devices. Depending on its power consumption and internal circuitry complexity, it might have an input current rating of a few amperes, say 1 - 5 A for typical applications. However, in systems with higher power requirements or when multiple components are powered simultaneously, this rating could be higher.

- Input Frequency (if applicable):

- If designed for AC input, it would operate with a specific input frequency, usually either 50 Hz or 60 Hz depending on the region's power grid standard. Some advanced models might be able to handle a wider frequency range or have the ability to adapt to different frequencies within certain limits to accommodate variations in power sources or specific application needs.

- Output Voltage Levels:

- The DS3800DMPC generates output voltages to communicate with other components in the turbine management system or to drive certain actuators or indicators. These output voltages could vary depending on the specific functions and connected devices. For example, it might have digital output pins with logic levels like 0 - 5 VDC for interfacing with digital circuits on other control boards or sensors. It could also have analog output channels with adjustable voltage ranges, perhaps from 0 - 10 VDC or 0 - 24 VDC for sending control signals to actuators like valve positioners or variable speed drives.

- Output Current Capacity:

- Each output channel would have a defined maximum output current that it can supply. For digital outputs, it might be able to source or sink a few tens of milliamperes, typically in the range of 10 - 50 mA. For analog output channels, the current capacity could be higher, depending on the power requirements of the connected actuators, say in the range of a few hundred milliamperes to a few amperes. This ensures that it can provide sufficient power to drive the connected components without overloading its internal circuits.

- Power Output Capacity:

- The total power output capacity of the board would be calculated by considering the sum of the power delivered through all its output channels. This gives an indication of its ability to handle the electrical load of the various devices it interfaces with in the turbine management system. It could range from a few watts for systems with relatively simple control requirements to several tens of watts for more complex setups with multiple power-consuming components.

- Processor Clock Speed:

- The microprocessor on the board would have a specific clock speed that determines its processing power and how quickly it can execute instructions. This could range from a few megahertz (MHz) for simpler, more dedicated control functions to hundreds of MHz or even higher for more advanced models capable of handling complex algorithms and large amounts of data in real-time. For example, a clock speed of 50 MHz might be sufficient for basic turbine control tasks, while a more powerful version could have a clock speed of 500 MHz or more for applications requiring rapid data analysis and decision-making.

- Control Resolution:

- In terms of its control over turbine parameters such as speed, temperature, or valve positions, it would have a certain level of control resolution. For example, it might be able to adjust the turbine speed in increments as fine as 1 RPM (revolutions per minute) or set temperature limits with a precision of ±0.1°C. This level of precision enables accurate regulation of the turbine's operation and is crucial for optimizing performance and maintaining safe operating conditions.

- Signal-to-Noise Ratio (SNR):

- When handling input signals from sensors or generating output signals for the turbine management system, it would have an SNR specification. A higher SNR indicates better signal quality and the ability to accurately process and distinguish the desired signals from background noise. This could be expressed in decibels (dB), with typical values depending on the application but aiming for a relatively high SNR to ensure reliable signal processing. In a noisy industrial environment with multiple electrical devices operating nearby, a good SNR is essential for precise control.

- Sampling Rate:

- For analog-to-digital conversion of input signals from sensors (such as temperature, pressure, and speed sensors), there would be a defined sampling rate. This is the number of samples it takes per second of the analog signal. It could range from a few hundred samples per second for slower-changing signals to several thousand samples per second for more dynamic signals, depending on the nature of the sensors and the control requirements. For example, when monitoring rapidly changing turbine speed during startup or shutdown, a higher sampling rate would be beneficial for capturing accurate data.

- Supported Protocols:

- It likely supports various communication protocols to interact with other devices in the turbine management system and for integration with control and monitoring systems. This could include standard industrial protocols like Modbus (both RTU and TCP/IP variants), Ethernet/IP, and potentially GE's own proprietary protocols. The specific version and features of each protocol that it implements would be detailed, including aspects like the maximum data transfer rate for each protocol, the number of supported connections, and any specific configuration options available for integration with other devices.

- Communication Interface:

- The DS3800DMPC would have physical communication interfaces, which could include Ethernet ports (perhaps supporting standards like 10/100/1000BASE-T), serial ports (like RS-232 or RS-485 for Modbus RTU), or other specialized interfaces depending on the protocols it supports. The pin configurations, cabling requirements, and maximum cable lengths for reliable communication over these interfaces would also be specified. For example, an RS-485 serial port might have a maximum cable length of several thousand feet under certain baud rate conditions for reliable data transmission in a large industrial facility.

- Data Transfer Rate:

- There would be defined maximum data transfer rates for sending and receiving data over its communication interfaces. For Ethernet-based communication, it could support speeds up to 1 Gbps (gigabit per second) or a portion of that depending on the actual implementation and the connected network infrastructure. For serial communication, baud rates like 9600, 19200, 38400 bps (bits per second), etc., would be available options. The chosen data transfer rate would depend on factors such as the amount of data to be exchanged, the communication distance, and the response time requirements of the system.

- Operating Temperature Range:

- It would have a specified operating temperature range within which it can function reliably. Given its application in industrial turbine environments that can experience significant temperature variations, this range might be something like -20°C to +60°C or a similar range that covers both the cooler areas within an industrial plant and the heat generated by operating equipment. In some extreme industrial settings like outdoor power plants in cold regions or in hot desert environments, a wider temperature range might be required.

- Storage Temperature Range:

- A separate storage temperature range would be defined for when the device is not in use. This range is usually wider than the operating temperature range to account for less controlled storage conditions, such as in a warehouse. It could be something like -40°C to +80°C to accommodate various storage environments.

- Humidity Range:

- There would be an acceptable relative humidity range, typically around 10% - 90% relative humidity (without condensation). Humidity can affect the electrical insulation and performance of electronic components, so this range ensures proper functioning in different moisture conditions. In environments with high humidity, like in some coastal industrial plants, proper ventilation and protection against moisture ingress are important to maintain the device's performance.

- Protection Level:

- It might have an IP (Ingress Protection) rating that indicates its ability to protect against dust and water ingress. For example, an IP20 rating would mean it can prevent the ingress of solid objects larger than 12mm and is protected against water splashes from any direction. Higher IP ratings would offer more protection in harsher environments. In dusty manufacturing facilities or those with occasional water exposure, a higher IP rating might be preferred.

- Dimensions:

- The physical size of the DS3800DMPC would be specified in terms of length, width, and height, usually measured in millimeters or inches. These dimensions are important for determining how it can be installed within an equipment rack or enclosure in an industrial turbine setup. For example, it might have dimensions of 8 inches by 6 inches by 1 inch to fit into a specific compartment or mounting frame within the turbine control cabinet.

- Weight:

- The weight of the device would also be provided, which is relevant for installation considerations, especially when it comes to ensuring proper mounting and support to handle its mass. A heavier control board might require sturdier mounting hardware and careful installation to prevent damage or misalignment.

- Connectors:

- It has specific types of connectors for its input and output connections. For example, it might have screw terminals for electrical connections, which can accommodate wires of a certain gauge range. There could also be cable connectors like right-angle cable connectors and ribbon connectors with specific pin assignments for different functions. The pinout and electrical specifications of these connectors would be clearly defined. For instance, a ribbon connector might have pins dedicated to power, ground, input signals, and output control signals, and the electrical characteristics of each pin (such as voltage levels and current-carrying capacity) would be specified.

- Resistors and Jumpers:

- As mentioned previously, it incorporates resistor network arrays and jumper switches. The resistors in the network arrays would have specific resistance ranges (e.g., from a few ohms to several kilohms) that are designed to perform specific electrical functions within the circuit. The jumper switches would be designed with specific configurations and positions to enable/disable functions or change signal paths, and their electrical characteristics and usage instructions would be detailed. For example, a jumper might be used to switch between different control modes or to connect/disconnect a specific sensor input to the control circuit.

Applications:DS3800DMPC

-

- In coal-fired, gas-fired, and oil-fired thermal power plants, the DS3800DMPC plays a crucial role in managing the operation of steam turbines. It controls various aspects such as turbine speed, steam flow rate, and temperature to ensure efficient and stable power generation. For example, during the startup process, it carefully ramps up the turbine speed while monitoring multiple parameters to avoid any mechanical stress or damage. Once the turbine is operating under load, it continuously adjusts the steam flow based on the grid demand to maintain a consistent power output.

- In gas turbine-based power plants, the control board is responsible for regulating parameters like fuel injection, compressor speed, and turbine inlet temperature. By precisely controlling these factors, it maximizes the power generation efficiency of the gas turbine and ensures that it can respond effectively to changes in load requirements. For instance, when there's a sudden increase in the electricity demand on the grid, the DS3800DMPC can quickly adjust the fuel flow to boost the power output of the gas turbine.

- Renewable Energy Integration:

- In combined cycle power plants that integrate both gas turbines and steam turbines (where waste heat from the gas turbine is used to generate steam for the steam turbine), the DS3800DMPC is essential for coordinating the operation of both turbine types. It optimizes the interaction between the gas and steam turbines to achieve higher overall energy conversion efficiency. For example, it can adjust the steam production based on the performance of the gas turbine to make the most of the available heat and generate more electricity.

- In some power plants that incorporate renewable energy sources like solar or wind along with gas or steam turbines for backup or grid stabilization purposes, the DS3800DMPC helps in smoothly integrating the different power sources. It can adjust the turbine output based on the availability and variability of the renewable energy input, ensuring a stable power supply to the grid.

- Refineries:

- In oil refineries, steam turbines are often used to drive various pumps, compressors, and other mechanical equipment. The DS3800DMPC controls these turbines to maintain the required rotational speeds and power outputs. For example, it ensures that the pumps that transport crude oil or refined products through the refinery operate at the correct speeds to maintain a consistent flow rate. It also adjusts the turbine operation based on changes in the process requirements, such as when different grades of oil are being processed or when there are variations in the throughput of the refinery.

- Gas turbines can also be used in refineries for power generation or to provide mechanical drive for certain critical processes. The control board manages these gas turbines to ensure reliable operation and efficient power delivery or mechanical power transfer, depending on the specific application within the refinery.

- Chemical Plants:

- In chemical manufacturing processes, steam turbines are commonly employed to drive agitators, mixers, and other process equipment. The DS3800DMPC precisely controls these turbines to meet the specific power and speed requirements of the chemical processes. For instance, in a polymerization reaction where precise mixing is crucial, it ensures that the turbine-driven mixer operates at the right speed to achieve the desired product quality.

- Gas turbines may be used in chemical plants for providing power or for driving compressors in gas compression systems. The control board is responsible for optimizing the performance of these gas turbines, adjusting parameters like fuel flow and turbine speed to meet the demands of the chemical processes while maintaining safety and efficiency.

- Cogeneration Plants:

- In cogeneration (combined heat and power, or CHP) facilities that simultaneously produce electricity and useful heat, the DS3800DMPC is used to control the gas or steam turbines. It manages the power generation aspect while also coordinating the extraction of heat from the turbine exhaust or other parts of the system for use in heating applications. For example, in a hospital's cogeneration plant, it ensures that the turbine generates enough electricity to meet the facility's power needs while also providing steam or hot water for heating and sterilization processes.

- In industrial cogeneration systems where the heat generated by the turbine is used for processes like drying, distillation, or space heating within the plant, the control board optimizes the turbine operation to balance electricity production and heat recovery. This allows for more efficient use of energy resources and reduces the overall reliance on external energy sources.

- District Heating Systems:

- In district heating networks where steam or hot water is distributed to multiple buildings for space heating and domestic hot water purposes, steam turbines are sometimes used as part of the energy generation and distribution infrastructure. The DS3800DMPC controls these turbines to ensure a consistent supply of heat and power. It can adjust the turbine operation based on the heating demand of the district, which may vary depending on factors like weather conditions and the time of day.

- Ship Propulsion:

- In ships that use gas or steam turbines for propulsion, the DS3800DMPC is crucial for controlling the turbines to achieve the desired speed and power output. It manages parameters like fuel injection, turbine speed, and exhaust conditions to optimize the performance of the propulsion system. For example, in a cruise ship with steam turbine propulsion, it ensures smooth acceleration and deceleration as the ship maneuvers in different sea conditions and adjusts the power output according to the ship's speed requirements.

- In naval vessels where gas turbines are commonly used for propulsion and to power onboard systems, the control board plays a vital role in maintaining the reliability and performance of the turbines. It can quickly respond to changes in operational requirements, such as during combat situations or when operating in different mission profiles.

Customization:DS3800DMPC

-

- Control Algorithm Optimization: GE or authorized partners can modify the device's firmware to optimize the control algorithms based on the unique characteristics of the turbine and its operating conditions. For example, in a gas turbine used in a power plant with a specific fuel blend or in an environment with frequent and rapid load changes, the firmware can be customized to implement more precise control strategies. This might involve adjusting PID (Proportional-Integral-Derivative) controller parameters or using advanced model-based control techniques to better regulate turbine speed, temperature, and power output in response to these specific conditions.

- Grid Integration Customization: When the turbine system is connected to a particular power grid with specific grid codes and requirements, the firmware can be tailored. For instance, if the grid demands specific voltage and reactive power support during different times of the day or under certain grid events, the firmware can be programmed to make the DS3800DMPC adjust the turbine's operation accordingly. This could include functions like automatically adjusting the turbine's power factor or providing voltage support to help stabilize the grid.

- Data Processing and Analytics Customization: The firmware can be enhanced to perform custom data processing and analytics based on the needs of the application. In a refinery where understanding the impact of different process parameters on turbine performance is crucial, the firmware can be configured to analyze specific sensor data in more detail. For example, it could calculate correlations between the flow rate of a particular chemical process and the temperature of the turbine exhaust to identify potential areas for optimization or early signs of equipment wear.

- Security and Communication Features: In an era where cyber threats are a significant concern in industrial systems, the firmware can be updated to incorporate additional security features. Custom encryption methods can be added to protect the communication data between the DS3800DMPC and other components in the system. Authentication protocols can also be strengthened to prevent unauthorized access to the control board's settings and functions. Additionally, the communication protocols within the firmware can be customized to work seamlessly with specific SCADA (Supervisory Control and Data Acquisition) systems or other plant-wide monitoring and control platforms used by the customer.

- User Interface and Data Display Customization:

- Custom Dashboards: Operators may prefer a customized user interface that highlights the most relevant parameters for their specific job functions or application scenarios. Custom programming can create intuitive dashboards that display information such as turbine speed trends, key temperature and pressure values, and any alarm or warning messages in a clear and easily accessible format. For example, in a chemical plant where the focus is on maintaining stable operation of a steam turbine-driven mixer, the dashboard can be designed to prominently show the mixer's speed and the temperature of the steam entering the turbine.

- Data Logging and Reporting Customization: The device can be configured to log specific data that is valuable for the particular application's maintenance and performance analysis. In a cogeneration plant, for instance, if tracking the heat recovery efficiency over time is important, the data logging functionality can be customized to record detailed information related to heat extraction and power generation. Custom reports can then be generated from this logged data to provide insights to operators and maintenance teams, helping them make informed decisions about equipment maintenance and process optimization.

- Input/Output Configuration:

- Power Input Adaptation: Depending on the available power source in the industrial facility, the input connections of the DS3800DMPC can be customized. If the plant has a non-standard power supply voltage or current rating, additional power conditioning modules can be added to ensure the device receives the appropriate power. For example, in a small industrial setup with a DC power source from a renewable energy system like solar panels, a custom DC-DC converter or power regulator can be integrated to match the input requirements of the control board.

- Output Interface Customization: On the output side, the connections to other components in the turbine management system, such as actuators (valves, variable speed drives, etc.) or other control boards, can be tailored. If the actuators have specific voltage or current requirements different from the default output capabilities of the DS3800DMPC, custom connectors or cabling arrangements can be made. Additionally, if there's a need to interface with additional monitoring or protection devices (like extra temperature sensors or vibration sensors), the output terminals can be modified or expanded to accommodate these connections.

- Add-On Modules:

- Enhanced Monitoring Modules: To improve the diagnostic and monitoring capabilities, extra sensor modules can be added. For example, high-precision temperature sensors can be attached to key components within the turbine system that are not already covered by the standard sensor suite. Vibration sensors can also be integrated to detect any mechanical abnormalities in the turbine or its associated equipment. These additional sensor data can then be processed by the DS3800DMPC and used for more comprehensive condition monitoring and early warning of potential failures.

- Communication Expansion Modules: If the industrial system has a legacy or specialized communication infrastructure that the DS3800DMPC needs to interface with, custom communication expansion modules can be added. This could involve integrating modules to support older serial communication protocols that are still in use in some facilities or adding wireless communication capabilities for remote monitoring in hard-to-reach areas of the plant or for integration with mobile maintenance teams.

- Enclosure and Protection:

- Harsh Environment Adaptation: In industrial environments that are particularly harsh, such as those with high levels of dust, humidity, extreme temperatures, or chemical exposure, the physical enclosure of the DS3800DMPC can be customized. Special coatings, gaskets, and seals can be added to enhance protection against corrosion, dust ingress, and moisture. For example, in a chemical processing plant where there is a risk of chemical splashes and fumes, the enclosure can be made from materials resistant to chemical corrosion and sealed to prevent any harmful substances from reaching the internal components of the control board.

- Thermal Management Customization: Depending on the ambient temperature conditions of the industrial setting, custom thermal management solutions can be incorporated. In a facility located in a hot climate where the control board might be exposed to high temperatures for extended periods, additional heat sinks, cooling fans, or even liquid cooling systems (if applicable) can be integrated into the enclosure to maintain the device within its optimal operating temperature range.

- Compliance Customization:

- Nuclear Power Plant Requirements: In nuclear power plants, which have extremely strict safety and regulatory standards, the DS3800DMPC can be customized to meet these specific demands. This might involve using materials and components that are radiation-hardened, undergoing specialized testing and certification processes to ensure reliability under nuclear conditions, and implementing redundant or fail-safe features to comply with the high safety requirements of the industry.

- Marine and Offshore Standards: In marine applications, especially for ships and offshore platforms, there are specific regulations regarding vibration tolerance, electromagnetic compatibility (EMC), and resistance to saltwater corrosion. The control board can be customized to meet these requirements. For example, in a ship's turbine control system, the DS3800DMPC might need to be modified to have enhanced vibration isolation features and better protection against the corrosive effects of seawater to ensure reliable operation during long voyages and in harsh marine environments.

Support and Services:DS3800DMPC

Our product technical support and services are designed to help our customers get the most out of their purchase. Our team of experts is available to assist with any technical issues or questions you may have regarding the product.

We offer a range of technical support options, including online resources such as FAQs, tutorials, and knowledge bases, as well as phone and email support for more complex issues.

In addition to technical support, we also offer a variety of services to help enhance the performance and functionality of the product. These services may include installation, customization, and training, depending on your specific needs.

Our goal is to provide our customers with the highest level of support and service possible, ensuring a positive and productive experience with our product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!