-

Power Supply

- Input Voltage: The board typically operates within a specific range of input voltages. Commonly, it accepts a DC voltage input, and the typical range is around +5V to +30V DC. However, the exact voltage range can vary depending on the specific model and application requirements. This voltage range is designed to be compatible with the power supply systems commonly found in industrial settings.

- Power Consumption: Under normal operating conditions, the power consumption of the DS3800HPLA usually falls within a certain range. It might consume approximately 3 to 10 watts on average. This value can vary based on factors such as the level of communication activity, the number of signals being processed, and the complexity of the functions it's performing.

-

Input Signals

- Digital Inputs

- Number of Channels: There are typically several digital input channels available, often in the range of 8 to 16 channels. These channels are designed to receive digital signals from various sources like switches, digital sensors, or status indicators within the industrial control system.

- Input Logic Levels: The digital input channels are configured to accept standard logic levels, often following TTL (Transistor-Transistor Logic) or CMOS (Complementary Metal-Oxide-Semiconductor) standards. A digital high level could be in the range of 2.4V to 5V, and a digital low level from 0V to 0.8V.

- Analog Inputs

- Number of Channels: It generally has multiple analog input channels, usually ranging from 4 to 8 channels. These channels are used to receive analog signals from sensors such as temperature sensors, pressure sensors, and vibration sensors.

- Input Signal Range: The analog input channels can handle voltage signals within specific ranges. For example, they might be able to accept voltage signals from 0 - 5V DC, 0 - 10V DC, or other custom ranges depending on the configuration and the types of sensors connected. Some models may also support current input signals, typically in the range of 0 - 20 mA or 4 - 20 mA.

- Resolution: The resolution of these analog inputs is usually in the range of 10 to 16 bits. A higher resolution allows for more precise measurement and differentiation of the input signal levels, enabling accurate representation of sensor data for further processing within the control system.

-

Output Signals

- Digital Outputs

- Number of Channels: There are typically several digital output channels, often in the range of 8 to 16 channels as well. These channels can provide binary signals to control components like relays, solenoid valves, or digital displays within the industrial control system.

- Output Logic Levels: The digital output channels can provide signals with logic levels similar to the digital inputs, with a digital high level in the appropriate voltage range for driving external devices and a digital low level within the standard low voltage range.

- Analog Outputs

- Number of Channels: It may feature a number of analog output channels, usually ranging from 2 to 4 channels. These can generate analog control signals for actuators or other devices that rely on analog input for operation, such as fuel injection valves or air intake vanes.

- Output Signal Range: The analog output channels can generate voltage signals within specific ranges similar to the inputs, such as 0 - 5V DC or 0 - 10V DC. The output impedance of these channels is usually designed to match typical load requirements in industrial control systems, ensuring stable and accurate signal delivery to the connected devices.

-

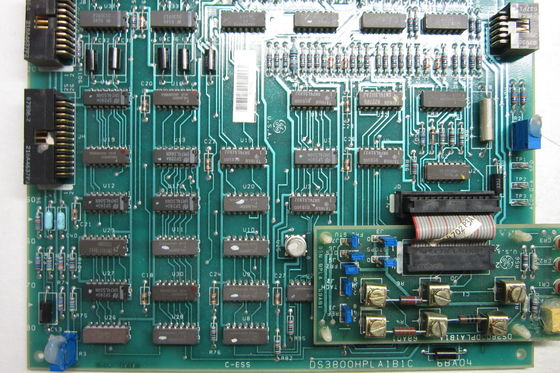

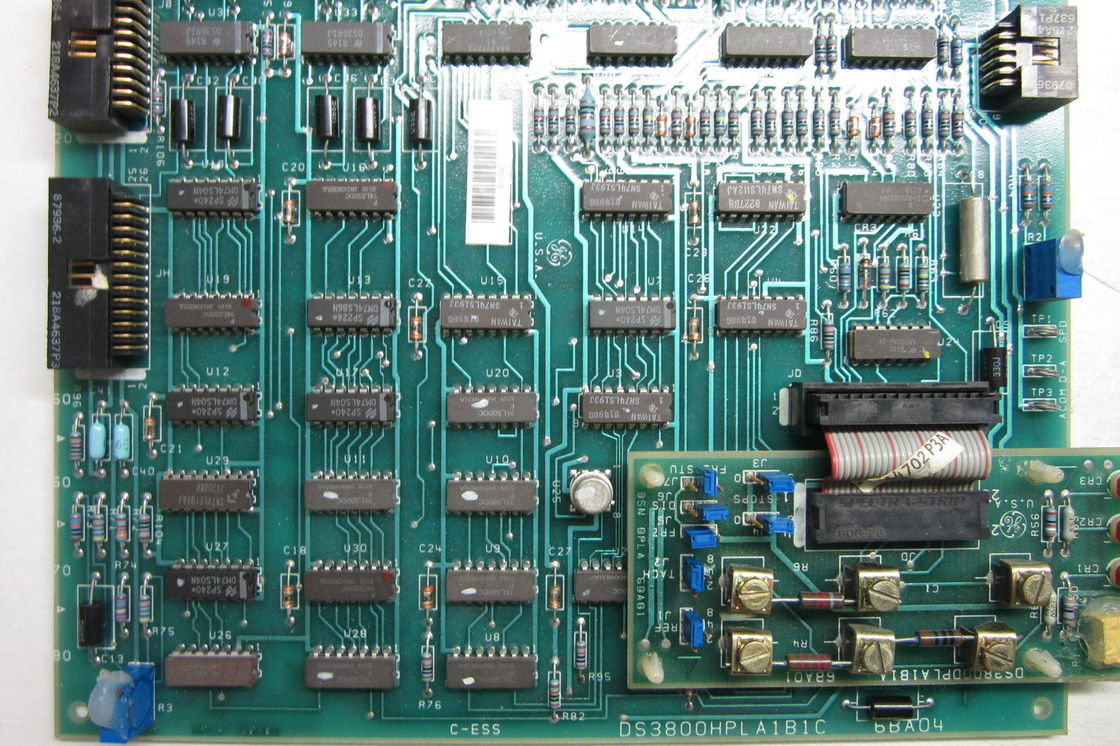

Processor

- Type and Clock Speed: The board incorporates a 32-bit microprocessor with a specific architecture and clock speed. The clock speed is typically in the range of tens to hundreds of MHz, depending on the model. For example, it might have a clock speed of 50 MHz or higher, which determines how quickly the microprocessor can execute instructions and process the incoming signals. A higher clock speed allows for faster data analysis and decision-making when handling multiple input signals simultaneously.

- Processing Capabilities: The microprocessor is capable of performing various arithmetic, logical, and control operations. It can execute complex control algorithms based on the programmed logic to process the input signals from sensors and generate appropriate output signals for actuators or for communication with other components in the system.

-

Memory

- EEPROM (Erasable Programmable Read-Only Memory): The two EEPROM sockets on the board can accommodate modules with a combined storage capacity that typically ranges from several kilobytes to a few megabytes. This memory is used to store firmware, configuration parameters, and other critical data that the board needs to operate and maintain its functionality over time. The ability to erase and reprogram the EEPROM allows for customization of the board's behavior and adaptation to different industrial processes and changing requirements.

- Random Access Memory (RAM): There is also a certain amount of onboard RAM for temporary data storage during operation. The RAM capacity might range from a few kilobytes to tens of megabytes, depending on the design. It is used by the microprocessor to store and manipulate data such as sensor readings, intermediate calculation results, and communication buffers as it processes information and executes tasks.

-

Ethernet Interface

- Speed and Standards: The Ethernet interface on the DS3800HPLA typically supports industry-standard Ethernet speeds, such as 10/100 Mbps. It adheres to Ethernet protocols like IEEE 802.3, enabling seamless integration with local area networks (LANs) and allowing for communication with other devices connected to the network, including computers, servers, and other industrial controllers. This interface facilitates remote monitoring, control, and data exchange over the network, making it possible to manage and oversee the operation of the industrial system from a central location.

- MAC Address: The board has a unique Media Access Control (MAC) address assigned to its Ethernet interface, which is used to identify it on the network and ensure proper communication with other devices.

-

RS-485 Interface

- Baud Rates: The RS-485 interface supports a range of baud rates for serial communication, typically from 9600 bits per second (bps) up to higher values like 115200 bps or even more, depending on the specific configuration and the requirements of the connected devices. This allows for flexible communication with other devices that use the RS-485 protocol, which is often used in industrial environments for long-distance or multi-drop communication scenarios.

- Protocols: It can support various serial communication protocols built on top of RS-485, depending on the application needs. For example, it might be used with Modbus RTU (Remote Terminal Unit) protocol for communication with multiple slave devices in a master-slave configuration, enabling efficient data exchange between different components in a distributed industrial control system.

- Operating Temperature: The DS3800HPLA is designed to operate within a specific temperature range, typically from -20°C to +60°C. This temperature tolerance allows it to function reliably in various industrial environments, from relatively cold outdoor locations to hot manufacturing areas or power plants where it may be exposed to heat generated by nearby equipment.

- Humidity: It can operate in environments with a relative humidity range of around 5% to 95% (non-condensing). This humidity tolerance ensures that moisture in the air does not cause electrical short circuits or corrosion of the internal components, enabling it to work in areas with different levels of moisture present due to industrial processes or environmental conditions.

- Electromagnetic Compatibility (EMC): The board meets relevant EMC standards to ensure its proper functioning in the presence of electromagnetic interference from other industrial equipment and to minimize its own electromagnetic emissions that could affect nearby devices. It is designed to withstand electromagnetic fields generated by motors, transformers, and other electrical components commonly found in industrial environments and maintain signal integrity and communication reliability.

- Board Size: The physical dimensions of the DS3800HPLA are usually in line with standard industrial control board sizes. It might have a length in the range of 6 - 12 inches, a width of 4 - 8 inches, and a thickness of 1 - 2 inches, depending on the specific design and form factor. These dimensions are chosen to fit into standard industrial control cabinets or enclosures and to allow for proper installation and connection with other components.

- Mounting Method: It is designed to be mounted securely within its designated housing or enclosure. It typically features mounting holes or slots along its edges to enable attachment to the mounting rails or brackets in the cabinet. The mounting mechanism is designed to withstand the vibrations and mechanical stress that are common in industrial environments, ensuring that the board remains firmly in place during operation and maintaining stable electrical connections.

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!