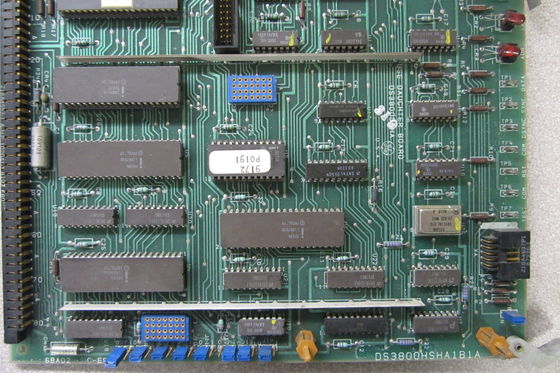

Product Description:DS3800HSHA

-

Dimensions and Form Factor: The DS3800HSHA has a relatively compact and standardized physical design. It measures approximately 175mm in length, 115mm in width, and 40mm in height. With a weight of around 0.5kg, it is lightweight enough to be easily integrated into control cabinets or other industrial equipment setups. Its size and weight make it convenient for installation in different industrial environments while taking up a reasonable amount of space within the overall system.

-

Enclosure and Mounting: The module is typically housed in an enclosure with an IP20 protection rating. This means it offers basic protection against solid objects larger than 12mm and provides no special protection against water ingress. The enclosure is designed to withstand the normal mechanical and environmental conditions found in industrial settings. It has mounting features that allow it to be securely attached to standard DIN rails or other mounting structures within control panels or equipment racks, ensuring stability during operation and ease of installation and removal for maintenance or replacement purposes.

-

Analog Input Types and Ranges: The DS3800HSHA is equipped with 8 input channels that can handle both voltage and current signals. For voltage inputs, it supports a range of 0 - 10V as well as ±10V, which enables it to interface with a wide variety of voltage-based sensors commonly used in industrial applications. When it comes to current inputs, it can accept signals in the range of 0 - 20mA and 4 - 20mA. These standard current ranges are widely used by sensors such as flow meters, pressure sensors with current output, and many other types of transducers, making the module highly versatile in terms of the types of sensors it can connect to.

-

Sampling Rate and Synchronization: Each of the 8 channels on the module has an impressive maximum sampling rate of 100kHz. This high sampling rate allows for the capture of rapidly changing analog signals with great precision, enabling detailed analysis and accurate representation of the dynamic behavior of the monitored parameters. Moreover, it supports multi-channel synchronous sampling, which is essential in applications where the relative timing and correlation between different signals need to be accurately maintained. For example, in monitoring the electrical and mechanical parameters of a complex industrial machine, synchronous sampling ensures that the data collected from different sensors at the same instant can be properly analyzed together to understand the overall system behavior.

-

Resolution and Accuracy: The module features a 16-bit resolution for analog-to-digital conversion. This high resolution means that it can distinguish very small changes in the input analog signals, providing a detailed and precise digital representation of the measured quantities. In terms of accuracy, it offers a full-scale accuracy of ±0.1%, which is quite high and ensures that the digital values obtained from the conversion closely match the actual analog input values. Additionally, it has a temperature drift specification of ±0.005%/°C, meaning that even with variations in ambient temperature, the module can maintain a relatively stable and accurate performance within the specified temperature range.

- Isolation Technology: One of the significant aspects of the DS3800HSHA is its use of optoelectronic isolation between the input channels and the rest of the system. This isolation provides a high level of electrical separation, with an isolation voltage rating of up to 2500Vrms. By physically separating the input side from the internal electronics of the module and the system it's connected to, it effectively prevents electrical interference, noise, and potential damage from high-voltage spikes or ground loops that might be present in the industrial environment. This isolation helps in maintaining the integrity of the input signals and the overall reliability of the control system.

-

Protocol Support: The module offers support for multiple communication protocols, including ProfiBus-DP, DeviceNet, and Modbus. These are widely used and well-established industrial communication protocols that enable seamless integration with a vast array of other devices, controllers, and systems in the industrial automation ecosystem. The ability to communicate via these different protocols provides flexibility in connecting the DS3800HSHA to existing control systems, whether they are based on a particular vendor's preferred protocol or need to interface with a diverse range of equipment from different manufacturers.

-

Communication Speed: It can achieve a relatively high communication transmission rate of up to 12Mbps, depending on the specific protocol and the configuration of the connected network. This fast communication speed allows for quick and efficient transfer of the acquired analog data from the module to the central control system or other connected devices, enabling real-time monitoring and control actions based on the latest sensor readings.

-

Temperature and Humidity Tolerance: The DS3800HSHA is designed to operate within a wide temperature range, from -20°C to +70°C. This broad temperature tolerance enables it to function reliably in various industrial settings, from cold environments like outdoor power generation facilities in colder regions to hot and humid manufacturing areas where industrial processes generate heat. It can also operate in environments with a relative humidity ranging from 5% to 95% (non-condensing), ensuring that normal levels of moisture in the air do not affect its electrical performance or cause damage to its internal components.

-

Power Supply: The module requires a 24VDC power supply with a tolerance of ±10%. This standard industrial voltage level is commonly available in most industrial control systems, making it easy to integrate the DS3800HSHA without the need for complex power conversion or additional power supply arrangements. The power consumption of the module is relatively low, with a maximum power draw of 5W, which helps in minimizing heat generation and contributes to its overall energy-efficient operation.

-

Power Generation: In the power generation industry, the DS3800HSHA plays a vital role in monitoring the condition of critical equipment. For example, it can be used to collect analog signals from sensors on generators, such as voltage and current sensors to monitor the electrical output, as well as temperature sensors on the generator windings and bearings to assess the thermal state. By continuously sampling these signals at high rates and with high accuracy, it provides valuable data to the control system for early detection of potential issues like overheating, abnormal electrical parameters, or mechanical wear. This enables operators to take preventive maintenance actions and ensure the stable and reliable operation of the power generation units.

-

Chemical Industry: In chemical manufacturing processes, the module is used to monitor parameters such as temperature, pressure, and flow rates within reactors, storage tanks, and piping systems. By connecting to various sensors throughout the chemical plant, it acquires the necessary analog signals and transmits them to the control system. This information is crucial for maintaining optimal process conditions, ensuring the safety of the chemical reactions, and controlling the quality of the final products. For instance, precise monitoring of temperature and pressure in a chemical reaction vessel can help prevent runaway reactions or overpressure situations that could lead to dangerous incidents.

-

Metallurgy Industry: In the metallurgy sector, the DS3800HSHA is employed to monitor the operation of equipment like high-temperature furnaces and rolling mills. It can receive analog signals from temperature sensors inside the furnace to control the heating process, as well as speed and pressure sensors on the rolling mill to ensure the proper shaping and quality of the metal products. The accurate and timely acquisition of these signals allows for precise control of the metallurgical processes, improving production efficiency and product quality.

Features:DS3800HSHA

- High-Quality Analog Inputs:

-

Versatile Input Ranges: The module offers a wide range of input options to accommodate various types of sensors. With the ability to handle voltage inputs from 0 - 10V and ±10V, as well as current inputs in the ranges of 0 - 20mA and 4 - 20mA, it can interface with numerous industrial sensors such as thermocouples, Resistance Temperature Detectors (RTDs), pressure sensors, flow meters, and many others. This versatility ensures that it can be easily integrated into different applications across multiple industries, regardless of the specific sensor output characteristics.

-

High Sampling Rate: Each of the 8 input channels has a maximum sampling rate of 100kHz. This high sampling frequency enables the capture of rapidly changing analog signals with great precision. It allows for detailed monitoring of dynamic processes, such as the transient electrical behavior of a power generator during startup or the fast pressure variations in a chemical reactor during a reaction. This precise sampling helps in obtaining a comprehensive understanding of the system's behavior and detecting even subtle changes in the monitored parameters.

-

Synchronous Sampling: The DS3800HSHA supports multi-channel synchronous sampling. This means that it can simultaneously sample all 8 input channels at precisely the same time intervals. In applications where the correlation between different signals is crucial, like in analyzing the mechanical and electrical interactions in a complex industrial machine or understanding the relationship between temperature, pressure, and flow in a process system, synchronous sampling ensures accurate data alignment. This enables more precise analysis and better decision-making based on the collected data.

-

High Resolution and Accuracy: Boasting a 16-bit resolution for analog-to-digital conversion, the module can distinguish very fine variations in the input analog signals. This high resolution translates to a more detailed digital representation of the measured quantities, providing greater precision in monitoring. Coupled with a full-scale accuracy of ±0.1% and a temperature drift of only ±0.005%/°C, it ensures that the digital values closely match the actual analog inputs over a wide range of operating conditions. This level of accuracy is essential for applications where precise control and reliable monitoring are required, such as in critical power generation or chemical manufacturing processes.

-

- Robust Isolation:

-

Optoelectronic Isolation: The module utilizes optoelectronic isolation between the input channels and the rest of the system. This isolation technique provides a high level of electrical separation, with an isolation voltage of up to 2500Vrms. By creating this physical barrier, it effectively blocks electrical interference, noise, and potential damage from high-voltage spikes or ground loops that are common in industrial environments. For example, in a factory with numerous large motors and electrical equipment generating electromagnetic interference, the optoelectronic isolation ensures that the analog signals received by the DS3800HSHA remain clean and undisturbed, safeguarding the integrity of the data being sent to the control system.

-

Enhanced System Protection: The isolation not only protects the module itself but also safeguards the entire control system. By preventing electrical issues on the input side from propagating to other components, it reduces the risk of system-wide failures. This is particularly important in industrial applications where a single electrical fault could have cascading effects on multiple processes or equipment, potentially leading to costly downtime and safety hazards.

-

- Multi-Protocol Support:

-

Industry-Standard Protocols: The DS3800HSHA supports several widely used industrial communication protocols, including ProfiBus-DP, DeviceNet, and Modbus. This broad protocol support enables seamless integration with a diverse range of existing industrial control systems, whether they are based on different vendor platforms or follow specific industry standards. For instance, it can communicate with Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, or other intelligent devices that use these protocols, facilitating easy data exchange and interoperability within the industrial automation ecosystem.

-

High Communication Speed: With a maximum communication transmission rate of up to 12Mbps, depending on the specific protocol in use, the module ensures quick and efficient transfer of the acquired analog data to the central control system or other connected devices. This fast communication speed allows for real-time monitoring and enables prompt control actions based on the latest sensor readings. In applications where immediate response is critical, such as in power grid control or emergency shutdown systems in industrial plants, the high-speed communication capability of the DS3800HSHA is invaluable.

-

- Wide Temperature and Humidity Range:

-

Temperature Tolerance: The module is designed to operate within a temperature range of -20°C to +70°C. This broad temperature tolerance allows it to function reliably in a variety of industrial settings, from cold outdoor environments like power generation stations in frigid regions to hot and humid manufacturing areas where industrial processes generate significant heat. Whether it's installed in an Arctic oil exploration facility or a tropical chemical plant, the DS3800HSHA can maintain its performance and continue to accurately acquire and transmit analog signals.

-

Humidity Tolerance: It can operate in environments with a relative humidity ranging from 5% to 95% (non-condensing). This humidity tolerance ensures that normal levels of moisture in the air do not affect its electrical performance or cause damage to its internal components. In industrial settings where water vapor or humidity variations are common due to processes like steam generation or open-air storage of materials, the module's ability to withstand these conditions makes it a robust choice for long-term use.

-

- Standard Power Supply Requirement:

-

24VDC Power Input: The DS3800HSHA operates on a 24VDC power supply with a tolerance of ±10%. This is a common and widely available voltage level in industrial control systems, making it straightforward to integrate the module into existing setups without the need for complex power conversion or additional power supply arrangements. The use of a standard power supply simplifies installation and reduces the potential for compatibility issues with other components in the system.

-

Low Power Consumption: With a maximum power draw of only 5W, the module is energy-efficient. This low power consumption not only helps in reducing overall energy costs but also minimizes heat generation within the module itself. By generating less heat, it can operate more stably within its specified temperature range and reduces the need for additional cooling measures, contributing to its reliability and ease of integration in various industrial environments.

-

- Self-Monitoring and Error Reporting:

-

Internal Diagnostics: The module is equipped with internal diagnostic capabilities that continuously monitor its own health and performance. It can detect issues such as abnormal input signal levels, communication errors, or component malfunctions within the module itself. This proactive self-monitoring allows for early identification of potential problems, enabling maintenance personnel to take corrective action before they escalate and cause system failures.

-

Error Reporting: When an error is detected, the DS3800HSHA can generate error reports that provide detailed information about the nature of the problem. These reports can be communicated to the central control system or displayed on a connected monitoring device, allowing technicians to quickly pinpoint the root cause of the issue. For example, if a sensor connection is faulty or an input signal exceeds its expected range, the error report will indicate which channel is affected and the specific conditions that led to the error, facilitating efficient troubleshooting and repair.

Technical Parameters:DS3800HSHA

-

Input Channels:

- Number: It features 8 analog input channels, allowing for multiple signals to be acquired simultaneously. This enables comprehensive monitoring of different parameters in an industrial process or system.

- Input Types: The channels can handle both voltage and current inputs. For voltage inputs, two ranges are supported: 0 - 10V and ±10V. For current inputs, the acceptable ranges are 0 - 20mA and 4 - 20mA. This flexibility in input types and ranges makes it compatible with a wide variety of industrial sensors, including but not limited to temperature sensors (such as RTDs and thermocouples), pressure sensors, flow meters, and level sensors.

-

Sampling Rate:

- Per Channel: Each individual channel has a maximum sampling rate of 100kHz. This high sampling frequency enables the module to capture rapid changes in analog signals accurately, which is crucial for monitoring dynamic processes or fast-varying parameters in industrial applications. For example, in applications like monitoring the electrical signals of a high-speed motor or the pressure fluctuations in a rapidly reacting chemical process, this high sampling rate ensures that no significant details are missed.

- Synchronous Sampling: The module supports multi-channel synchronous sampling. This means that all 8 channels can sample their respective input signals at precisely the same time intervals. This feature is essential when analyzing the correlation between different signals or when precise time alignment of multiple measurements is required. For instance, in a power generation system where you need to simultaneously monitor voltage, current, and temperature to assess the overall health of the generator, synchronous sampling ensures that the data from all these channels is synchronized for accurate analysis.

-

Resolution and Accuracy:

- Resolution: The DS3800HSHA offers a 16-bit resolution for analog-to-digital conversion. With 16 bits, it can represent the input analog signal with a high level of detail, allowing for the detection of very small variations in the measured quantity. This enables precise monitoring and control in applications where fine distinctions in parameters matter, such as in precision manufacturing or in monitoring the performance of sensitive electrical equipment.

- Full-Scale Accuracy: The module has a full-scale accuracy of ±0.1%. This means that over the entire range of the input signal (for example, from 0 to 10V for the voltage input range), the digital output value obtained from the analog-to-digital conversion will be within ±0.1% of the actual analog input value. This high level of accuracy ensures reliable and consistent measurements for accurate decision-making in industrial control systems.

- Temperature Drift: The temperature drift specification is ±0.005%/°C. This indicates that as the ambient temperature changes within the operating temperature range, the accuracy of the module's measurements will change at a rate of ±0.005% per degree Celsius. While some drift is inevitable with temperature variations, this relatively low rate helps maintain good performance over a wide range of environmental conditions.

- Isolation Method: The input channels of the DS3800HSHA are isolated from the rest of the system using optoelectronic isolation. This technique physically separates the input side electrically from the internal electronics of the module and the connected system, creating a barrier against electrical interference and potential damage.

- Isolation Voltage: It has an isolation voltage rating of up to 2500Vrms. This high isolation voltage provides significant protection against electrical noise, voltage spikes, and ground loops that are common in industrial environments. For example, in an industrial setting with multiple electrical equipment operating simultaneously, where there may be large voltage fluctuations or electrical noise from motors, generators, or power lines, the high isolation voltage ensures that the analog input signals are kept clean and undisturbed, safeguarding the integrity of the data being acquired by the module.

- Supported Protocols: The module supports several well-known industrial communication protocols, including ProfiBus-DP, DeviceNet, and Modbus. This wide protocol support allows it to integrate with a diverse range of industrial control systems, Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, and other devices that use these protocols. It provides flexibility in configuring and connecting the DS3800HSHA within different automation architectures.

- Communication Speed: The maximum communication transmission rate that can be achieved depends on the specific protocol used but can reach up to 12Mbps. This high-speed communication capability enables quick and efficient transfer of the acquired analog data from the module to the central control system or other connected devices. It ensures that real-time monitoring and control actions can be based on the most up-to-date sensor readings, which is crucial in applications where timely responses are essential, such as in power grid management or in emergency shutdown systems of industrial plants.

- Operating Temperature: The module is designed to operate within a temperature range of -20°C to +70°C. This broad temperature tolerance allows it to function reliably in various industrial environments, from cold outdoor locations like power generation sites in colder regions to hot and humid manufacturing areas where industrial processes generate heat. It ensures that the module's performance remains consistent across different climate conditions and industrial settings.

- Relative Humidity: It can operate in environments with a relative humidity ranging from 5% to 95% (non-condensing). This humidity tolerance means that normal levels of moisture in the air will not affect the module's electrical performance or cause damage to its internal components. In industrial applications where humidity levels can vary due to processes like steam generation or in areas with high ambient humidity, the DS3800HSHA can continue to operate without issues.

- Protection Level: The module has an IP20 protection rating. This indicates that it provides basic protection against solid objects larger than 12mm and offers no special protection against water ingress. While it is not designed for use in extremely wet or dusty environments without additional protection measures, it is suitable for installation in typical industrial control cabinets or equipment racks where it is shielded from direct exposure to harsh elements.

- Power Supply Voltage: The DS3800HSHA requires a 24VDC power supply with a tolerance of ±10%. This standard industrial voltage level is commonly available in most industrial control systems, making it easy to integrate the module into existing setups. It simplifies the power supply design and reduces the likelihood of compatibility issues with other components in the system.

- Power Consumption: The maximum power consumption of the module is 5W. This relatively low power draw has several benefits. It helps in reducing overall energy costs, minimizes heat generation within the module itself, and allows for more stable operation within its specified temperature range. By generating less heat, it may not require additional cooling measures in many standard industrial environments, further enhancing its ease of use and reliability.

- Dimensions: The module has approximate dimensions of 175mm (length) x 115mm (width) x 40mm (height). These compact dimensions make it suitable for installation in control cabinets or equipment racks where space is often at a premium. It can be easily mounted alongside other components in an industrial control system without taking up excessive space.

- Weight: It weighs approximately 0.5kg. The lightweight nature of the module simplifies handling during installation, maintenance, or replacement procedures, and also has implications for the structural design of the equipment or cabinet in which it is installed, as it places less mechanical stress on the mounting structure.

|

Applications:DS3800HSHA

-

Heating, Ventilation, and Air Conditioning (HVAC) Systems:

-

Air Handling Units: In commercial buildings, office complexes, and industrial facilities, the DS3800HSHA is used to monitor and control HVAC systems. For air handling units, it can connect to temperature sensors to measure the temperature of the incoming and outgoing air. Humidity sensors can also be interfaced with the module to monitor the humidity levels of the air. Additionally, it can monitor the flow rates of chilled water or hot water used for heating and cooling purposes by connecting to appropriate flow meters. Based on this data, the HVAC control system can adjust the operation of the air handling units to maintain comfortable indoor conditions and optimize energy consumption.

-

Variable Refrigerant Flow (VRF) Systems: In modern HVAC systems like VRF systems, the DS3800HSHA can monitor parameters such as the refrigerant pressure and temperature at different points in the system. It can also measure the power consumption of the compressor and other components. This information helps in optimizing the performance of the VRF system, ensuring efficient cooling and heating, and detecting any potential issues with the refrigerant circuit or the equipment.

-

Energy Management: In building automation systems, the DS3800HSHA can be integrated to monitor energy consumption of various electrical and mechanical systems in the building. It can connect to power meters to measure the electricity consumption of different areas or equipment. Additionally, it can interface with sensors that monitor the usage of other energy sources like gas or steam. By collecting this data, energy management systems can analyze energy usage patterns, identify areas for energy savings, and implement strategies to optimize the overall energy efficiency of the building.

Customization:DS3800HSHA

- Firmware Customization:

- Control Algorithm Customization: Depending on the unique characteristics of the application and the specific industrial process it's integrated into, the firmware of the DS3800HSHA can be customized to implement specialized control algorithms. For example, in a wind turbine application, custom algorithms can be developed to optimize the power generation based on the relationship between wind speed, blade pitch, and generator output. The firmware can use the high-resolution analog inputs from the module to precisely calculate the optimal blade pitch adjustment in real-time, taking into account factors like wind turbulence and the specific power curve of the turbine.

In a chemical manufacturing process where maintaining a precise temperature profile is crucial for product quality, the firmware can be programmed to control heating or cooling elements based on complex temperature-dependent reaction kinetics. It can analyze the temperature data acquired by the DS3800HSHA from multiple sensors within the reactor and adjust the control signals accordingly to ensure the reaction proceeds within the desired temperature range.

- Fault Detection and Handling Customization: The firmware can be configured to detect and respond to specific faults in a customized manner. Different applications may have distinct failure modes or components that are more prone to issues. In a solar power plant, where the performance of solar panels can be affected by factors like shading, dust accumulation, or temperature variations, the firmware can be programmed to closely monitor the signals from irradiance sensors and temperature sensors connected to the DS3800HSHA. If a sudden drop in power output is detected due to shading, the firmware can trigger specific actions such as alerting the maintenance team with detailed location information and suggesting possible corrective measures like trimming nearby vegetation or adjusting the panel orientation.

In an automotive engine testing setup, the firmware can be customized to detect issues with fuel injection or combustion based on the pressure and temperature signals received from the module. For example, if abnormal pressure fluctuations in the combustion chamber are detected, the firmware can immediately stop the test, notify the operator with specific error codes related to the pressure sensor and the engine component involved, and even suggest possible solutions like checking the fuel injector or the spark plug.

- Communication Protocol Customization: To integrate with existing industrial control systems that may use different communication protocols, the DS3800HSHA's firmware can be updated to support additional or specialized protocols. In a power plant that has legacy systems still using older serial communication protocols for some of its monitoring and control functions, the firmware can be modified to enable seamless data exchange with those systems.

For applications aiming to connect with modern cloud-based monitoring platforms or Industry 4.0 technologies, the firmware can be enhanced to work with protocols like MQTT (Message Queuing Telemetry Transport) or OPC UA (OPC Unified Architecture). This allows for efficient remote monitoring, data analytics, and control from external systems, enabling better integration with broader enterprise-level management and optimization strategies. For instance, in a building automation system, the firmware can be programmed to send energy consumption data in a format compatible with cloud-based analytics platforms using MQTT, allowing facility managers to analyze trends and optimize energy usage remotely.

- Data Processing and Analytics Customization: The firmware can be customized to perform specific data processing and analytics tasks relevant to the application. In a railway system, the firmware can analyze the data from axle counters and speed sensors (if their analog signals are processed by the DS3800HSHA) over time to predict potential track wear or maintenance needs. It could calculate the average speed of trains passing through specific sections, detect any abnormal acceleration or deceleration patterns, and use this information to schedule track inspections or maintenance activities more proactively.

In a food processing plant, the firmware can analyze temperature and humidity data from different zones of the production facility to ensure optimal conditions for food safety and quality. It might calculate the cumulative exposure time to certain temperature and humidity ranges and trigger alerts if these exceed predefined thresholds for specific food products, helping to prevent spoilage or contamination.

-

Input Signal Conditioning Customization:

-

Amplification and Offset Adjustment: Depending on the types of sensors used in a particular application, the input signal conditioning of the DS3800HSHA can be customized. Some sensors may output very weak analog signals that need amplification to be within the optimal range for the module's analog-to-digital conversion. Custom amplification circuits can be added or integrated to boost these weak signals. Additionally, offset adjustments can be made to account for any DC offset in the sensor signals, ensuring accurate digitization. For example, in a precision measurement application where a sensor has a very low output voltage range close to the noise floor, custom amplification can be configured to bring the signal to a level that the module can handle precisely.

-

Filtering Customization: The module's input channels can be customized with different filtering options to remove unwanted noise or interference specific to the application environment. In an industrial setting with a lot of electrical machinery generating electromagnetic interference, custom filters can be designed to target and eliminate specific frequencies of noise that could affect the accuracy of the analog signals being acquired. For instance, if there is significant 50Hz or 60Hz power line interference present, notch filters can be added to the input channels to suppress these frequencies and improve signal quality.

-

Input/Output (I/O) Expansion and Adaptation:

-

Digital I/O Expansion: Depending on the complexity of the industrial process and the need to interface with additional digital devices, the DS3800HSHA can be customized with digital I/O expansion. Extra digital input and output channels can be added to the module, either through external expansion boards or by integrating additional circuitry. This allows for more comprehensive control and monitoring, such as interfacing with digital sensors, relays, or indicator lights that are part of the overall industrial system. For example, in a manufacturing process where there are multiple digital status indicators and emergency stop switches that need to be monitored and controlled, digital I/O expansion can be implemented to connect these devices to the module.

-

Analog Output Customization: In some applications, having analog output capabilities in addition to the existing analog inputs can be beneficial. Custom analog output channels can be added to the DS3800HSHA to generate control signals for actuators or other devices that rely on analog input for operation. For instance, in a process control system where the module is used to monitor temperature and pressure, and based on these readings, it needs to control the position of a valve (which may require an analog voltage or current signal), custom analog output channels can be configured to provide the appropriate control signals.

-

Power Input Customization: In industrial settings with non-standard power supply configurations, the power input of the DS3800HSHA can be adapted. For example, in an offshore oil platform where the power supply is subject to significant voltage fluctuations and harmonic distortions due to the complex electrical infrastructure, custom power conditioning modules like DC-DC converters or advanced voltage regulators can be added to the module. These ensure that the module receives stable and appropriate power, safeguarding it from power surges and maintaining its reliable operation.

In a remote solar power generation site where the power generated by solar panels is stored in batteries and the voltage levels vary depending on the battery state of charge, similar power input customization can be done to make the DS3800HSHA compatible with the available power supply and operate optimally under those conditions.

- Enclosure and Protection Customization:

- Harsh Environment Adaptation: In industrial environments that are particularly harsh, such as those with high levels of dust, humidity, extreme temperatures, or chemical exposure, the physical enclosure of the DS3800HSHA can be customized. In a desert-based power plant where dust storms are common, the enclosure can be designed with enhanced dust-proof features like air filters and gaskets to keep the internal components of the module clean. Special coatings can be applied to protect the module from the abrasive effects of dust particles.

In a chemical processing plant where there is a risk of chemical splashes and fumes, the enclosure can be made from materials resistant to chemical corrosion and sealed to prevent any harmful substances from reaching the internal components of the module. Additionally, in extremely cold environments like those in Arctic oil and gas exploration sites, heating elements or insulation can be added to the enclosure to ensure the DS3800HSHA starts up and operates reliably even in freezing temperatures.

- Thermal Management Customization: Depending on the ambient temperature conditions of the industrial setting, custom thermal management solutions can be incorporated. In a facility located in a hot climate where the module might be exposed to high temperatures for extended periods, additional heat sinks, cooling fans, or even liquid cooling systems (if applicable) can be integrated into the enclosure to maintain the device within its optimal operating temperature range.

In a data center where multiple DS3800HSHA modules are installed in a confined space and heat dissipation is a concern, a more elaborate cooling system can be designed to ensure that each module operates within its specified temperature limits, preventing overheating and potential performance degradation or component failure.

- Compliance Customization:

- Nuclear Power Plant Requirements: In nuclear power plants, which have extremely strict safety and regulatory standards, the DS3800HSHA can be customized to meet these specific demands. This might involve using materials and components that are radiation-hardened, undergoing specialized testing and certification processes to ensure reliability under nuclear conditions, and implementing redundant or fail-safe features to comply with the high safety requirements of the industry.

For example, in a nuclear-powered naval vessel or a nuclear power generation facility, the module would need to meet stringent safety and performance standards to ensure the safe operation of the systems that rely on the DS3800HSHA for analog signal acquisition in power generation, cooling, or other relevant applications. Redundant power supplies, multiple layers of error detection and correction in the firmware, and enhanced electromagnetic shielding might be implemented to meet these requirements.

- Aerospace and Aviation Standards: In aerospace applications, there are specific regulations regarding vibration tolerance, electromagnetic compatibility (EMC), and reliability due to the critical nature of aircraft operations. The DS3800HSHA can be customized to meet these requirements. For example, it might need to be modified to have enhanced vibration isolation features and better protection against electromagnetic interference to ensure reliable operation during flight.

Support and Services:DS3800HSHA

Our product technical support and services include:

- 24/7 technical support via phone, email, or live chat

- Product installation assistance and troubleshooting

- Remote access support for faster issue resolution

- Regular software updates and patches for improved performance and security

- Access to a knowledge base with articles and tutorials

- On-site support for more complex issues or installations

- Customized training programs for your team

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!