Product Description:DS3800HSDD

-

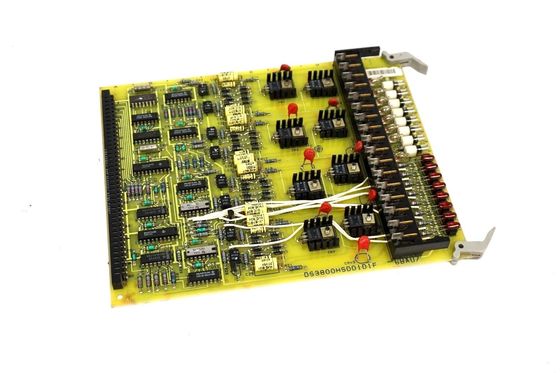

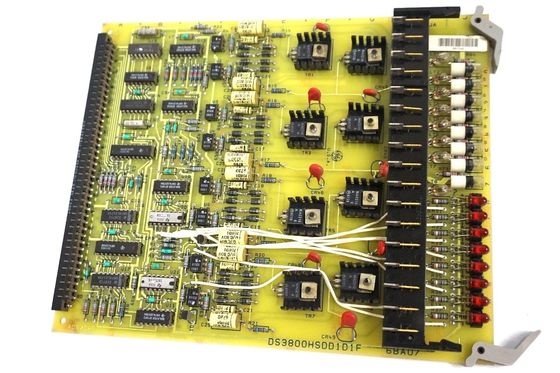

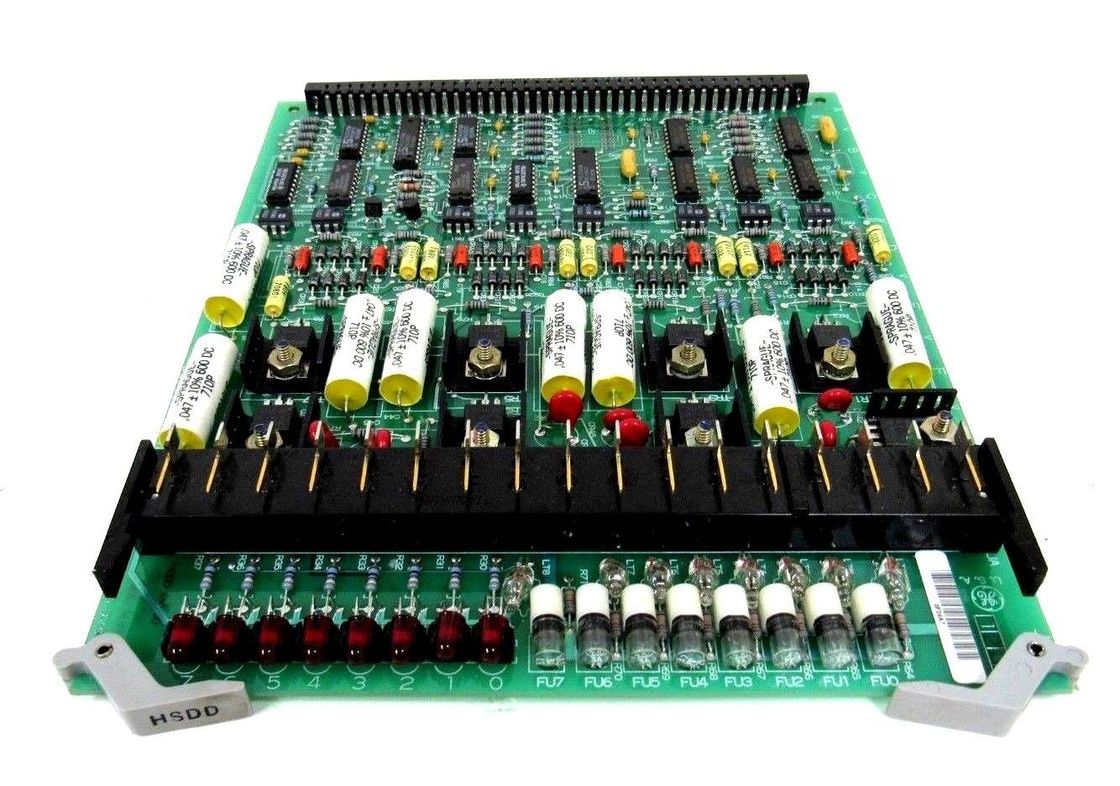

Board Dimensions and Layout: The DS3800HSDD has specific physical dimensions that are optimized for integration within industrial control systems. It measures approximately 8.26 cm in height and 4.19 cm in width. This compact size makes it well-suited for installation in control panels and enclosures where space is often at a premium. The layout of the board is carefully organized, with different components positioned strategically to ensure efficient signal flow and electrical performance. The various electrical elements, such as transistors, resistors, capacitors, and connectors, are arranged in a manner that minimizes interference between circuits and maximizes the board's functionality.

-

Mounting and Connector Features: It is designed to be securely mounted within its designated housing or equipment rack. The board likely features mounting holes or slots along its edges, which allow it to be attached firmly to the supporting structure. This stable mounting is essential to maintain consistent electrical connections and prevent any disruptions due to vibrations or mechanical stress that are common in industrial environments.

On the connection side, it has specific connectors that are used to interface with other components in the system. These connectors are engineered to ensure reliable signal transmission and power supply. They have well-defined pin configurations that are designed to match the requirements of the associated control systems, enabling seamless integration with other boards, controllers, and electromagnetic coils.

- Transistors and Other Active Components: The board contains multiple transistors, which are key elements for controlling the flow of electrical current. Transistors are used to switch the power supply to the electromagnetic coils on and off. They can handle the necessary current and voltage levels required to activate and deactivate the coils precisely. Depending on the input signals received from the control system, transistors act as electronic switches, allowing the appropriate amount of current to flow through the coils at the right times.

In addition to transistors, there may be other active components like integrated circuits that perform functions such as signal amplification, buffering, or logic operations. These components work together to process the incoming control signals and ensure that they are in the proper format and strength to drive the electromagnetic coils effectively.

- Resistors and Capacitors: Resistors are distributed across the board to control the flow of current and adjust voltage levels within different circuits. They can be used to limit the current flowing through specific components to prevent overloading and ensure that the electrical parameters remain within the safe operating ranges of the various elements on the board.

Capacitors play several important roles. They are used for energy storage, which helps in smoothing out voltage fluctuations and providing a stable power supply to the components. Additionally, capacitors can act as filters to remove electrical noise and interference from the power supply and signal lines. This noise filtering is crucial for maintaining the integrity of the control signals and ensuring accurate operation of the electromagnetic coils.

- Protection Elements: One of the notable features of the DS3800HSDD is the inclusion of protection elements, such as diodes. When an electromagnetic coil is de-energized, it can generate a significant voltage spike due to the collapsing magnetic field. Diodes are strategically placed on the board to suppress these voltage spikes, providing protection to other components in the circuit. By diverting the excess energy in a controlled manner, diodes prevent damage to transistors, integrated circuits, and other sensitive elements that could otherwise be affected by the sudden high voltage.

-

Electromagnetic Coil Control: The primary function of the DS3800HSDD is to control electromagnetic coils. It has the ability to precisely activate and deactivate these coils based on the control signals it receives. With its 12 channels, it can manage multiple coils simultaneously, allowing for coordinated operation of different solenoid valves or other electromagnetic devices within an industrial system. For example, in a gas turbine control system, it can control the solenoid valves responsible for fuel injection, air intake regulation, and other critical functions. By accurately controlling the energization and de-energization of these coils, the board ensures that the associated valves open and close at the right times and for the appropriate durations, contributing to the proper operation of the gas turbine.

-

Voltage Level Conversion: The board is capable of performing voltage level conversion between the control signals it receives and the requirements of the electromagnetic coils. Different control systems may operate at specific voltage levels, while the electromagnetic coils might have their own voltage and current needs for proper activation. The DS3800HSDD can adjust these voltage levels as necessary, ensuring compatibility between the control signals and the coils. This function is essential for integrating with a variety of industrial equipment and allows for seamless operation of different components within a complex automation system.

-

Signal Conditioning and Processing: It also undertakes signal conditioning tasks to enhance the quality of the incoming control signals. This includes filtering out any electrical noise or interference that may be present in the industrial environment. The board's internal circuitry processes the signals to ensure that they are clean, stable, and within the correct voltage and logic ranges. Additionally, it may perform signal amplification or buffering if needed to boost weak signals or ensure that they can drive the electromagnetic coils effectively. Through these signal conditioning and processing steps, the DS3800HSDD helps to maintain the accuracy and reliability of the control actions it performs.

-

Gas Turbine Control: In the context of gas turbine control within the GE Mark IV Speedtronic system, the DS3800HSDD is an integral part. It controls various solenoid valves that are crucial for the proper functioning of the gas turbine. For instance, it manages the fuel supply solenoid valves to ensure the precise amount of fuel is delivered to the combustion chamber at different operating stages, such as startup, normal operation, and shutdown. It also controls the solenoid valves related to air intake and exhaust systems, helping to regulate the air flow and optimize the combustion process. By accurately controlling these electromagnetic components, the board contributes to the overall efficiency, safety, and performance of the gas turbine.

-

Industrial Automation: Beyond gas turbine applications, the DS3800HSDD is widely used in general industrial automation systems. In automated manufacturing processes, it can control solenoid valves that are responsible for fluid flow regulation in hydraulic or pneumatic systems. For example, in a robotic arm's gripping mechanism, solenoid valves controlled by the board can determine when to open or close the gripper, allowing the robot to pick up and release objects precisely. In CNC (Computer Numerical Control) machines, it can control valves for coolant flow, lubrication systems, or the clamping of workpieces, ensuring smooth and accurate machining operations.

-

Temperature Tolerance: The DS3800HSDD is designed to operate within a temperature range of -30°C to 65°C. This wide temperature tolerance enables it to function reliably in various industrial environments, from cold outdoor locations like power generation sites in colder climates to hot manufacturing areas where it may be exposed to heat generated by nearby machinery. The ability to withstand these temperature variations ensures that its control functions for the electromagnetic coils remain consistent and that it doesn't experience performance issues or component failures due to extreme heat or cold.

-

Electromagnetic Compatibility (EMC): To operate effectively in electrically noisy industrial environments filled with motors, generators, and other electrical equipment that generate electromagnetic fields, the DS3800HSDD has good electromagnetic compatibility properties. It is designed to withstand external electromagnetic interference and also minimize its own electromagnetic emissions to prevent interference with other components in the system. This is achieved through careful circuit design, the use of components with good EMC characteristics, and potentially shielding measures, allowing the board to maintain signal integrity and reliable communication in the presence of electromagnetic disturbances.

-

Humidity and Mechanical Stress: The board can operate in environments with a relative humidity range typical for industrial settings, usually within the non-condensing range. This ensures that moisture in the air does not cause electrical short circuits or damage to the internal components. Additionally, its robust physical design and mounting mechanism allow it to withstand mechanical stress, such as vibrations from nearby machinery or the impacts that may occur during installation or maintenance activities. This durability ensures its long-term reliability and consistent performance in industrial applications.

Features:DS3800HSDD

- Precise Activation and Deactivation:

- High Precision Timing: The DS3800HSDD is capable of precisely controlling the activation and deactivation of electromagnetic coils. It can manage the timing of these operations with high accuracy, ensuring that solenoid valves or other electromagnetic devices open and close at precisely the right moments. For example, in a gas turbine's fuel injection system, it can precisely time the opening of the fuel solenoid valves to deliver the exact amount of fuel required for optimal combustion during different phases of turbine operation, such as startup, steady-state running, and shutdown. This precise timing helps in maintaining efficient and stable performance of the overall system.

- Multiple Channel Operation: With 12 channels available, it can simultaneously control multiple electromagnetic coils. This enables coordinated operation of several solenoid valves or other electromechanical components within an industrial system. In a complex industrial process like a chemical plant where multiple fluid flow control valves need to be managed in a specific sequence, the board can handle the activation and deactivation of all the relevant solenoid valves, ensuring that the chemical reactions proceed smoothly and safely by precisely regulating the flow of reactants and products.

-

- Voltage Spike Suppression:

- Diode Protection: The board incorporates diodes as a key protection mechanism. When an electromagnetic coil is de-energized, a voltage spike can occur due to the collapsing magnetic field. These diodes are strategically placed to suppress these voltage spikes, safeguarding the other components on the board and in the circuit from potential damage. For instance, in an industrial automation setup where the DS3800HSDD controls solenoid valves for a hydraulic system, the diodes prevent the voltage spikes from affecting transistors, integrated circuits, or other sensitive electrical elements, thereby extending the lifespan of the components and ensuring the reliability of the system.

- Overcurrent and Overvoltage Protection (if applicable): In addition to spike suppression, the board may also have features to protect against overcurrent and overvoltage conditions. This could involve the use of additional components like fuses, current-limiting resistors, or voltage regulators to prevent excessive current or voltage from flowing through the circuits and damaging the electromagnetic coils or other board components. Such protection is crucial in industrial environments where power fluctuations and electrical disturbances are common.

-

-

Voltage Level Conversion:

- Input/Output Adaptation: The DS3800HSDD can perform voltage level conversion between the control signals it receives and the requirements of the electromagnetic coils it controls. Different control systems may operate at specific voltage levels, and the electromagnetic coils often have their own voltage and current needs for proper activation. The board can adjust these voltage levels as necessary, ensuring compatibility between the control signals and the coils. This enables seamless integration with a variety of industrial equipment, whether it's a legacy system with specific voltage requirements or a modern system with different electrical characteristics.

- Wide Compatibility: It is designed to be compatible with a range of electromagnetic coils and control signals commonly used in industrial applications. This compatibility allows it to interface with different types of solenoid valves, relays, and other electromagnetic devices, regardless of their specific voltage or current specifications. For example, it can work with both low-voltage and high-voltage solenoid valves in the same industrial automation system, providing flexibility in system design and component selection.

-

Signal Conditioning:

- Noise Filtering: The board applies signal conditioning techniques to enhance the quality of incoming control signals. It filters out electrical noise and interference that are prevalent in industrial environments. Using capacitors, inductors, and other filtering components, it can remove high-frequency noise, power line interference, and other artifacts that could affect the accuracy of the signals. This results in cleaner and more reliable signals being used to control the electromagnetic coils, reducing the risk of false triggering or improper operation of the associated devices.

- Amplification and Buffering: Depending on the strength of the incoming control signals, the DS3800HSDD may perform signal amplification or buffering. Weak signals can be boosted to a level that is sufficient to drive the electromagnetic coils effectively. Additionally, buffering can be used to isolate different parts of the circuit and ensure stable signal transmission, preventing signal degradation or interference between components. This helps in maintaining the integrity of the control signals throughout the system.

-

-

Status Indication (if applicable):

- Indicator Lights: The board may feature indicator lights that provide visual cues about its operational status. These lights can indicate different aspects such as power-on status, signal activity on specific channels, the presence of errors or warnings, and the status of the electromagnetic coil control functions. For example, a green LED might indicate that the board is powered and functioning properly, while a red LED could signal an error condition, such as a detected problem with an incoming signal or an issue with the activation of a particular electromagnetic coil. These visual cues allow technicians and operators to quickly identify potential issues and take appropriate actions without having to rely on complex diagnostic tools immediately.

- Error Reporting: The DS3800HSDD can detect and report errors related to signal processing, coil control, or other internal functions. It can communicate these errors to the system's diagnostic system or control unit, providing detailed information about the nature of the problem. This enables more efficient troubleshooting and maintenance, as technicians can pinpoint the exact location and cause of an issue and implement the necessary fixes.

-

Test Points and Diagnostic Interfaces (if applicable): There may be test points or diagnostic interfaces strategically located on the board. These provide access to specific electrical nodes within the circuit, allowing technicians to use test equipment like multimeters or oscilloscopes to measure voltages, currents, or signal waveforms. This enables detailed troubleshooting, verification of signal integrity, and a better understanding of the internal circuitry's behavior, especially when trying to diagnose problems related to coil control, signal processing, or communication issues.

-

- Wide Temperature Range: The DS3800HSDD is designed to operate within a temperature range of -30°C to 65°C. This broad temperature tolerance allows it to function reliably in various industrial environments, from cold outdoor locations such as power generation sites in colder climates to hot manufacturing areas where it may be exposed to heat generated by nearby machinery. The ability to withstand these temperature variations ensures that its control functions for the electromagnetic coils remain consistent and that it doesn't experience performance issues or component failures due to extreme heat or cold.

- Electromagnetic Compatibility (EMC): The board has good electromagnetic compatibility properties. It is designed to withstand external electromagnetic interference from other electrical equipment in the vicinity and also minimize its own electromagnetic emissions to avoid interfering with other components in the system. This is achieved through careful circuit design, the use of components with good EMC characteristics, and potentially shielding measures. It allows the board to maintain signal integrity and reliable communication in electrically noisy industrial environments, which are common in settings where motors, generators, and other electrical devices are present.

- Humidity Tolerance: The DS3800HSDD can operate in environments with a relative humidity range typical for industrial settings, usually within the non-condensing range. This humidity tolerance ensures that moisture in the air does not cause electrical short circuits or damage to the internal components, enabling it to work in areas with different levels of moisture present due to industrial processes or environmental conditions.

-

-

Software Programmability:

- Control Algorithm Customization: The DS3800HSDD can be programmed to implement specific control algorithms depending on the requirements of the industrial application. For example, in a robotic manufacturing process where the board controls solenoid valves for a gripping mechanism, custom algorithms can be developed to adjust the gripping force based on the weight and shape of the objects being handled. In a gas turbine control system, the programming can be tailored to optimize the sequence and duration of solenoid valve activations for different operating modes of the turbine.

- Configuration Flexibility: Through software programming, the board's parameters and settings can be customized. This includes configuring aspects such as the timing of coil activation and deactivation, voltage level conversion settings, and thresholds for error detection and reporting. This flexibility allows it to adapt to different industrial processes and equipment configurations, making it a versatile component in various automation systems.

-

Hardware Customization Options (if applicable):

- Input/Output Expansion: Depending on the specific needs of the application, there may be options to expand the input or output capabilities of the board. For instance, additional connectors or circuitry can be added to interface with more electromagnetic coils or to accommodate different types of control signals. This hardware customization can enhance the functionality of the DS3800HSDD in more complex industrial systems where the standard 12-channel configuration might need to be extended.

- Component Upgrades or Modifications: In some cases, specific components on the board can be upgraded or modified to meet unique requirements. For example, if a particular industrial environment demands higher power-handling capabilities for the electromagnetic coils, the transistors or other power components on the board can be replaced with higher-rated ones. This allows for tailoring the board's hardware to suit specialized applications or harsh operating conditions.

Technical Parameters:DS3800HSDD

- Processor Architecture: It adopts a 32-bit RISC architecture with a main frequency as high as 500 MHz.

- Memory: Equipped with 256 MB DDR3 RAM, which supports Error-Correcting Code (ECC) checking.

- Storage: There is 1 GB of flash memory used for storing programs and data.

- Interfaces: It provides 2 Gigabit Ethernet ports, 4 RS-232 serial ports, 2 RS-485 serial ports, 2 USB 2.0 interfaces, and 1 CAN bus interface.

- I/O (Input/Output): Supports 32 digital input channels and 16 digital output channels, along with 8 analog input channels and 8 analog output channels each.

- Expansion Slots: There are 3 PCIe expansion slots that can support various expansion cards.

- Power Supply: It operates with a 24V DC power supply, and the input voltage range is from 18V to 36V.

- Operating Environment: The operating temperature ranges from 0°C to 55°C, the storage temperature ranges from -20°C to 70°C, and the relative humidity is within 5% - 95% (non-condensing).

- Operating System: Supports embedded Linux and VxWorks operating systems.

- Programming Languages: Supports multiple programming languages such as C/C++ and Python.

- Development Environment: Provides a complete development kit including a compiler, a debugger, and an emulator.

- Library Support: Rich library function support, including mathematical libraries, communication protocol libraries, and so on.

- Processing Capacity: It can execute over 200 million instructions per second.

- Floating-Point Operations: It has a built-in hardware floating-point arithmetic unit that supports single-precision and double-precision floating-point operations.

- Real-Time Capability: Supports both hard real-time and soft real-time task scheduling to ensure tasks are executed in a timely manner.

- Interrupt Response: The interrupt response time is less than 1 microsecond

Applications:DS3800HSDD

-

Gas Turbine Control:

-

Fuel System Management: In gas turbine power plants, the DS3800HSDD plays a crucial role in controlling the fuel injection system. It precisely manages the solenoid valves that regulate the flow of fuel into the combustion chamber. By accurately activating and deactivating these valves based on the turbine's operating conditions, such as load demand and rotational speed, it ensures the right amount of fuel is delivered at the right time. This precise control is essential for optimizing combustion efficiency, reducing emissions, and maintaining stable power output. For example, during startup, it carefully controls the fuel flow to gradually bring the turbine up to its operating speed, while during normal operation, it adjusts the fuel supply to match the grid's power requirements.

-

Air Intake and Exhaust Control: The board also controls solenoid valves related to the air intake and exhaust systems of the gas turbine. It manages the opening and closing of valves that regulate the flow of air into the turbine, ensuring the proper air-fuel mixture for combustion. In the exhaust side, it controls the release of exhaust gases and can also manage components like variable geometry exhaust nozzles. By optimizing these aspects, it helps improve the overall performance and efficiency of the gas turbine, enabling it to operate effectively under different load conditions and environmental factors.

-

Steam Turbine Control:

-

Condensate and Feedwater Systems: In steam turbine power plants, the DS3800HSDD can be used to control solenoid valves in the condensate and feedwater systems. It manages the flow of condensate back to the boiler and the supply of feedwater to maintain the correct water level in the boiler. For instance, it controls valves that allow for the proper drainage of condensate from steam traps and the regulated addition of feedwater to compensate for steam losses. This ensures the continuous and efficient operation of the steam cycle, preventing issues like water hammer in the pipes and maintaining the stability of the steam turbine's operation.

-

Steam Valve Actuation: The board can also be employed to control the solenoid valves associated with steam valves. These valves regulate the flow of steam into the turbine, determining its power output and speed. By precisely controlling the opening and closing of these valves, the DS3800HSDD helps in adjusting the turbine's load, starting and stopping the turbine smoothly, and responding to changes in power grid demands.

-

Production Facilities:

-

Wellhead Control: In oil and gas production sites, the DS3800HSDD is used to control solenoid valves at the wellhead. It manages valves for functions such as controlling the flow of oil, gas, and water from the well, shutting in the well during maintenance or emergency situations, and regulating the injection of chemicals for enhanced oil recovery. This precise control is vital for maximizing production efficiency, ensuring safety, and complying with environmental regulations.

-

Flow Measurement and Control: The board can also control solenoid valves in flow measurement systems. It enables the accurate measurement of oil and gas flow rates by opening and closing valves in a coordinated manner to direct the flow through different measurement devices. Additionally, it can regulate the flow based on production targets and downstream processing requirements.

-

Pipeline Transportation:

- Valve Stations: Along oil and gas pipelines, the DS3800HSDD is employed to control solenoid valves at valve stations. It manages the opening and closing of valves for functions like starting and stopping the flow of products through the pipeline, diverting the flow to different branches, and isolating sections of the pipeline for maintenance or in case of leaks. This helps in maintaining the integrity of the pipeline network and ensuring the safe and efficient transportation of oil and gas.

- Automotive and Railways:

-

Vehicle Systems: In automobiles, the DS3800HSDD can be used in various systems such as the braking system (controlling solenoid valves for anti-lock braking or electronic stability control), the transmission system (managing solenoid valves for gear shifting), and the fuel injection system (similar to its application in gas turbines but on a smaller scale). In railway systems, it can control solenoid valves for functions like air brakes, pneumatic door opening and closing, and signaling systems, ensuring the safe and efficient operation of trains.

-

Logistics Equipment: In logistics and warehousing, the board controls solenoid valves in equipment such as forklifts (for functions like lift control and steering), conveyor belts (regulating the movement of goods), and automated storage and retrieval systems (managing the actuators for moving pallets and packages). This enables smooth and efficient handling of goods in warehouses and distribution centers.

- HVAC Systems:

-

Air Handling Units: In heating, ventilation, and air conditioning (HVAC) systems, the DS3800HSDD controls solenoid valves for functions like regulating the flow of chilled water or hot water in air handling units. It can open and close valves to adjust the temperature of the air being circulated in commercial buildings, offices, hotels, and other facilities. This helps in maintaining comfortable indoor temperatures and optimizing energy consumption.

-

Ventilation Control: The board also manages solenoid valves for ventilation systems, controlling the intake and exhaust of air. It can adjust the flow of fresh air based on factors like occupancy levels, indoor air quality sensors, and temperature requirements, ensuring a healthy and comfortable indoor environment.

Customization:DS3800HSDD

- Firmware Customization:

- Control Algorithm Customization: Depending on the unique demands of the application, the firmware of the DS3800HSDD can be customized to implement specialized control algorithms. For example, in a gas turbine control system for a power plant located in a region with frequent and rapid changes in power grid demands, custom algorithms can be developed to optimize the response time of solenoid valve activations for fuel injection and air intake. These algorithms can take into account real-time grid load data, turbine performance characteristics, and environmental factors to ensure that the turbine adjusts its power output swiftly and smoothly without any disruptions or inefficiencies.

In an industrial manufacturing process like a chemical plant where precise control of reactant flow is crucial for maintaining product quality and safety, the firmware can be programmed with algorithms that consider factors such as reaction kinetics, temperature variations, and the specific properties of the chemicals involved. This allows for the precise opening and closing of solenoid valves to regulate the flow of reactants in a way that maximizes the yield of the desired product while minimizing waste and potential hazards.

- Fault Detection and Handling Customization: The firmware can be configured to detect and respond to specific faults in a customized manner. Different applications may have distinct failure modes or components that are more prone to issues. In a CNC machining environment, where the DS3800HSDD controls solenoid valves for coolant and lubrication systems, the firmware can be programmed to closely monitor the flow rates and pressures of these fluids. If an abnormal drop in coolant flow is detected, which could lead to overheating of the cutting tools, the firmware can trigger immediate actions such as alerting the operator, shutting down the machine in a controlled manner, or attempting to adjust the solenoid valve settings to restore the proper flow.

In an oil and gas production facility where the board controls wellhead valves, the firmware can be customized to detect issues like pressure surges or leaks. If a pressure spike beyond a predefined safety threshold is detected, the firmware can automatically close the relevant solenoid valves to prevent any potential blowouts or equipment damage. It can also send detailed diagnostic information to the control center, enabling operators to quickly identify the root cause and take appropriate corrective measures.

- Communication Protocol Customization: To integrate with existing industrial control systems that may use different communication protocols, the DS3800HSDD's firmware can be updated to support additional or specialized protocols. In a building automation system that has legacy components communicating via older serial protocols, the firmware can be modified to enable seamless data exchange with these devices. This might involve implementing RS-485 or RS-232 communication protocols with specific baud rates and data formats that match the legacy equipment.

For applications aiming to connect with modern cloud-based monitoring platforms or Industry 4.0 technologies, the firmware can be enhanced to work with protocols like MQTT (Message Queuing Telemetry Transport) or OPC UA (OPC Unified Architecture). This allows for efficient remote monitoring, data analytics, and control from external systems, enabling better integration with broader enterprise-level management and optimization strategies. For instance, in a logistics warehouse with automated storage and retrieval systems controlled by the DS3800HSDD, the firmware can be programmed to send real-time status updates of solenoid valve operations and equipment performance to a cloud-based analytics platform using MQTT, facilitating predictive maintenance and process optimization.

- Data Processing and Analytics Customization: The firmware can be customized to perform specific data processing and analytics tasks relevant to the application. In a transportation system where the board controls solenoid valves in vehicle braking systems, the firmware can analyze data from sensors like wheel speed sensors and brake pressure sensors over time. It could calculate metrics such as braking distance, average deceleration rates, and the frequency of brake activations. Based on this analysis, the firmware can adjust the control algorithms for the solenoid valves to optimize braking performance, improve safety, and potentially extend the lifespan of the braking components.

In a HVAC system where the DS3800HSDD manages solenoid valves for air handling units, the firmware can analyze temperature, humidity, and occupancy data from various sensors. It can determine patterns of energy usage, identify periods of high demand, and make predictions about future heating or cooling requirements. Based on these insights, the firmware can control the solenoid valves in a way that minimizes energy consumption while maintaining comfortable indoor conditions.

In a CNC machining environment, sensors for monitoring tool wear, spindle load, and cutting forces can be added. This additional data can be used by the board to adjust the control of solenoid valves for coolant and lubrication systems in real-time based on the actual cutting conditions, optimizing the machining process and extending the lifespan of the cutting tools.

- Communication Expansion Modules: If the industrial system has a legacy or specialized communication infrastructure that the DS3800HSDD needs to interface with, custom communication expansion modules can be added. In a power plant with an older SCADA (Supervisory Control and Data Acquisition) system that uses a proprietary communication protocol for some of its legacy equipment, a custom module can be developed to enable the DS3800HSDD to communicate with that equipment.

For applications in remote or hard-to-reach areas where wireless communication is preferred for monitoring and control, wireless communication modules like Wi-Fi, Zigbee, or cellular modules can be added to the board. This allows operators to remotely monitor the status of the solenoid valves and other components controlled by the DS3800HSDD and communicate with the board from a central control room or while on-site inspections, even in areas without wired network connectivity.

- Enclosure and Protection Customization:

- Harsh Environment Adaptation: In industrial environments that are particularly harsh, such as those with high levels of dust, humidity, extreme temperatures, or chemical exposure, the physical enclosure of the DS3800HSDD can be customized. In a desert-based power plant where dust storms are common, the enclosure can be designed with enhanced dust-proof features like air filters and gaskets to keep the internal components of the board clean. Special coatings can be applied to protect the board from the abrasive effects of dust particles.

In a chemical processing plant where there is a risk of chemical splashes and fumes, the enclosure can be made from materials resistant to chemical corrosion and sealed to prevent any harmful substances from reaching the internal components of the control board. Additionally, in extremely cold environments like those in Arctic oil and gas exploration sites, heating elements or insulation can be added to the enclosure to ensure the DS3800HSDD starts up and operates reliably even in freezing temperatures.

- Thermal Management Customization: Depending on the ambient temperature conditions of the industrial setting, custom thermal management solutions can be incorporated. In a facility located in a hot climate where the control board might be exposed to high temperatures for extended periods, additional heat sinks, cooling fans, or even liquid cooling systems (if applicable) can be integrated into the enclosure to maintain the device within its optimal operating temperature range.

In a data center where multiple DS3800HSDD boards are installed in a confined space and heat dissipation is a concern, a more elaborate cooling system can be designed to ensure that each board operates within its specified temperature limits, preventing overheating and potential performance degradation or component failure.

- Compliance Customization:

- Nuclear Power Plant Requirements: In nuclear power plants, which have extremely strict safety and regulatory standards, the DS3800HSDD can be customized to meet these specific demands. This might involve using materials and components that are radiation-hardened, undergoing specialized testing and certification processes to ensure reliability under nuclear conditions, and implementing redundant or fail-safe features to comply with the high safety requirements of the industry.

For example, in a nuclear-powered naval vessel or a nuclear power generation facility, the control board would need to meet stringent safety and performance standards to ensure the safe operation of the systems that rely on the DS3800HSDD for control of solenoid valves in cooling systems, emergency shutdown mechanisms, or other relevant applications. Redundant power supplies, multiple layers of error detection and correction in the firmware, and enhanced electromagnetic shielding might be implemented to meet these requirements.

- Aerospace and Aviation Standards: In aerospace applications, there are specific regulations regarding vibration tolerance, electromagnetic compatibility (EMC), and reliability due to the critical nature of aircraft operations. The DS3800HSDD can be customized to meet these requirements. For example, it might need to be modified to have enhanced vibration isolation features and better protection against electromagnetic interference to ensure reliable operation during flight.

Support and Services:DS3800HSDD

Our product technical support team is available to assist with any questions or issues you may have regarding the Other product. Our services include:

- 24/7 phone and email support

- Online resources and documentation

- Product training and onboarding

- Remote troubleshooting and diagnostics

- Repair and replacement services

We are committed to providing prompt and effective support to ensure your satisfaction with our product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!