Product Description:DS3800HVDB1K1G

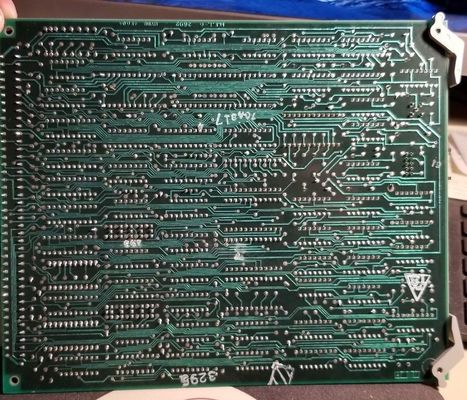

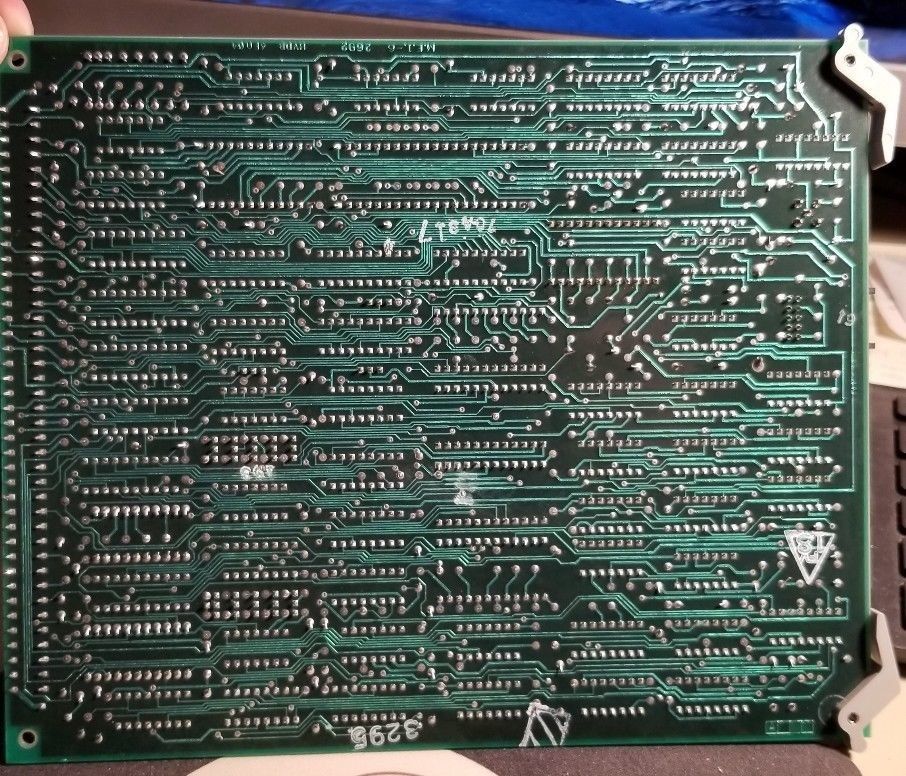

- Overall Layout: The board has a distinct physical layout designed for practicality and integration within specific systems. One end of the DS3800HVDB1K1G features a modular connector, which serves as the main interface for connecting it to other components within the larger system. This modular design allows for easy and standardized connection, ensuring reliable data transfer and electrical communication with adjacent boards or devices.

At the other end, there is a retaining lever or bar, which plays a crucial role in securing the board in its designated position. Between these retaining bars, a 20-pin connector is installed. This 20-pin connector provides additional connection points that can be used for various purposes, such as interfacing with specific monitors, display devices, or other components that require video signal input or other related data exchange.

- Memory Modules: The board is equipped with multiple Electrically Erasable Programmable Read-Only Memory (EEPROM) modules. These EEPROMs are integral to the board's functionality as they store the firmware and other codes that govern the processing and operation of the driver. The firmware stored in these modules contains the essential instructions that enable the board to perform its specific functions, such as generating the appropriate video signals, handling communication with other components, and managing various aspects of the display or control process related to the system it's integrated into.

- Electronic Code Update: One of the notable features of the DS3800HVDB1K1G is its ability to have the code within the EEPROM modules updated electronically. This means that operators or technicians don't need to physically remove the modules from the board to update the firmware or make changes to the programming. Instead, through a designated electronic interface or communication protocol, the code can be updated remotely or directly while the board remains installed in the system. This convenience ensures that the latest firmware, which might include bug fixes, performance enhancements, or new features, can be easily incorporated into the board's operation. It allows for keeping the driver up to date with the evolving requirements of the overall system and enables seamless integration with any software or system upgrades that occur over time.

-

Ease of Installation: The board is specifically engineered for quick and straightforward installation within a drive or relevant equipment enclosure. The design considerations for installation include features like the modular connector and the retaining lever, which make it easy to position the board correctly and secure it firmly in place. This simplicity in installation reduces the time and effort required during setup, minimizing the potential for errors and ensuring that the system can be brought online or updated quickly.

-

Module Handling: When it comes to maintenance or replacement of the EEPROM modules, the process is designed to be relatively user-friendly. To remove a module, although no special tools are required, a simple screwdriver can be used to carefully pry the module out of its socket. For installation, the process is equally straightforward. The new or replacement module is simply placed onto the socket and gently pushed into place until it is properly seated. This ease of module handling makes it convenient for technicians to perform upgrades or replacements as needed, without the need for complex procedures or specialized equipment.

-

Industrial Control: In the realm of industrial control, the DS3800HVDB1K1G is a key component. For example, in a power plant where gas turbines are in operation, it works in conjunction with other elements of the Speedtronic system. It can assist in presenting crucial visual information related to the turbine's operation, such as real-time monitoring of parameters like speed, temperature, and pressure. The video signals generated by the board can be used to display this information on monitors located in the control room, allowing operators to make informed decisions and take appropriate actions to ensure the smooth and efficient running of the turbine.

-

Broad Range of Applications: Beyond industrial control in power generation, this video driver board finds utility in numerous other domains. As an MVME single-board computer, it can play a vital role in automation. In an automated production line, it can be used to drive displays that show the status of robots, sensors, and actuators, enabling operators to monitor and manage the production process effectively. In the aerospace sector, it might be involved in controlling the display systems for navigation and communication within an aircraft, presenting critical flight information to the pilots. In the medical equipment field, it could be used to drive the display interfaces of instruments like CT scanners and MRI machines, ensuring that medical professionals can view the scanned images and relevant diagnostic data clearly. Additionally, in military applications, it can be part of systems that control fire control systems and communication equipment, providing visual feedback and interface for operators to manage and operate these complex systems.

-

Repair Services: The DS3800HVDB1K1G can be serviced by professional technicians. Companies like AX Control offer repair services with varying turnaround times. For instance, they typically provide a standard repair service that takes around 1 - 2 weeks. However, for urgent situations where downtime needs to be minimized, they can also offer expedited repair services with a turnaround time of 48 - 72 hours. During the repair process, detailed repair reports are often generated, which document the issues found and the actions taken to fix them. Additionally, upon completion of the repair, a warranty certificate is usually provided to give the customer peace of mind regarding the quality of the repair work.

-

Warranty Period: Generally, components like GE's PLCs, HMIs, and turbine control boards, including the DS3800HVDB1K1G, come with a warranty period. Typically, this warranty lasts for about 3 years, although the specific duration may vary depending on the vendor or the terms of the purchase agreement. The warranty provides assurance to the customers that in case of any manufacturing defects or issues that arise within the specified period, the board can be repaired or replaced at no additional cost.

Features:DS3800HVDB1K1G

Robust Design for Industrial Environments:

-

Wide Temperature Tolerance: The DS3800HVDB1K1G is engineered to operate within a wide temperature range that is typical of industrial settings. It can withstand both high and low temperatures, ensuring reliable performance whether installed in a hot factory environment or in a cold outdoor installation, such as in power substations or oil rigs. This temperature tolerance helps to prevent performance degradation or component failure due to extreme temperature variations, contributing to the overall reliability of the board.

-

Resistance to Vibration and Shock: In industrial environments where equipment may be subjected to vibrations from machinery or occasional shocks, the board is designed to be resilient. Its physical construction and component mounting are likely to incorporate features that minimize the impact of vibrations and shocks on its internal components. This durability ensures that it can maintain its functionality even in harsh operating conditions, reducing the risk of downtime due to physical damage.

Redundancy and Error Handling:

-

Built-in Redundancy: To enhance reliability, the board may incorporate certain redundancy features. For example, it could have redundant power inputs or backup components for critical functions to ensure continuous operation in case of a component failure. This redundancy helps to safeguard against single-point failures and increases the overall availability of the system that relies on the DS3800HVDB1K1G.

-

Error Detection and Reporting: The board is equipped with mechanisms for detecting errors and anomalies during its operation. It can monitor various aspects such as video signal integrity, communication link status, and internal component health. If an issue is detected, it can generate error messages or alerts that can be communicated to operators or maintenance personnel. This proactive error handling enables quick response to problems, minimizing the impact on system operation and facilitating timely repairs or corrective actions.

Seamless Integration with Speedtronic System:

-

Coordinated Operation: As part of the GE Speedtronic system, the DS3800HVDB1K1G is designed to work in harmony with other components. It can exchange data and signals with other boards, controllers, and modules within the Speedtronic architecture to ensure the seamless operation of the overall system. For example, it can receive input signals related to the status of industrial equipment (such as a gas turbine's operational parameters) and generate video signals that accurately reflect this information on the display for operators to monitor and manage.

-

Enhanced System Functionality: The integration with the Speedtronic system allows for enhanced overall functionality. The video driver board can contribute to the comprehensive control and monitoring capabilities of the system by providing visual feedback on critical processes. This visual representation helps operators make informed decisions promptly, improving the efficiency and reliability of the industrial processes being controlled.

Broad Compatibility with Other Systems:

-

Multi-Industry Applicability: Beyond its integration within the Speedtronic system, the DS3800HVDB1K1G demonstrates broad compatibility with other systems in various industries. In automation, it can interface with different types of sensors, actuators, and control devices to support the operation of automated production lines. In aerospace, it can integrate with flight control systems, navigation equipment, and communication systems to display relevant flight information. In medical applications, it can work with imaging devices like CT scanners and MRI machines to present diagnostic images clearly. This wide compatibility makes it a versatile component that can be utilized in diverse technological contexts.

-

Protocol and Interface Compatibility: The board is likely to support multiple communication protocols and interfaces, enabling it to connect with a wide range of devices. This could include Ethernet-based protocols for networked communication, serial interfaces for legacy device integration, or specialized protocols used in specific industries. The ability to communicate with different devices using various protocols enhances its adaptability and integration potential within complex and heterogeneous systems.

High-Quality Video Signal Output:

-

Accurate Signal Generation: The DS3800HVDB1K1G is designed to produce high-quality video signals that are crucial for clear and reliable visual display. It can generate video signals with precise timing, resolution, and color accuracy, depending on the requirements of the connected display devices. This ensures that the information presented on monitors, whether in an industrial control room, an aircraft cockpit, or a medical imaging facility, is displayed accurately and is easy to read and interpret.

-

Compatibility with Multiple Displays: The board is likely to be compatible with a variety of display types and technologies, including different monitor sizes, aspect ratios, and resolutions. This versatility allows it to be integrated into diverse systems where various display devices are used. For example, it can support both standard-definition and high-definition displays, enabling seamless connection to different monitors based on the specific needs of the application, such as in a manufacturing plant with different display setups for different production lines or in a hospital with multiple types of medical imaging monitors.

Video Signal Customization and Control:

-

Adjustable Parameters: The board may offer the ability to customize video signals based on specific requirements. Operators can potentially adjust parameters such as brightness, contrast, color saturation, and refresh rate to optimize the visual display according to the ambient lighting conditions, user preferences, or the nature of the information being displayed. This customization ensures that the video output is always presented in the most suitable way for effective viewing and decision-making.

-

Synchronized Display: In applications where multiple displays are used or where the video signal needs to be synchronized with other system events, the DS3800HVDB1K1G can likely provide features to enable such synchronization. For example, in a control room monitoring multiple aspects of a complex industrial process, the video signals for different displays showing different parameters (like temperature, pressure, and flow rate) can be synchronized to provide a coherent and comprehensive visual representation of the entire process at any given time.

Quick and Easy Installation:

-

Designed for Drive Integration: The board is specifically engineered for straightforward installation within a drive or relevant equipment enclosure. It features a modular connector at one end, which simplifies the connection process by providing a standardized interface for plugging it into the system. Along with this, the retaining lever or bar on the other end helps in securely fastening the board in its designated position. This design minimizes the time and effort required for installation, reducing the potential for errors and enabling technicians to quickly integrate the board into the system during setup or replacement procedures.

-

Reduced Installation Complexity: The absence of complicated installation procedures or the need for specialized tools (apart from a simple screwdriver for module handling) makes the installation process accessible to a wider range of technicians. This simplicity is especially beneficial in industrial environments where quick turnaround times for equipment installation or maintenance are often crucial.

User-Friendly Module Handling:

-

Simple Module Removal: When it comes to replacing or upgrading the EEPROM modules, the process is designed to be intuitive and easy for users. To remove a module, a screwdriver can be used to gently pry it out of its socket. This straightforward method eliminates the need for complex extraction tools or procedures, making it convenient for technicians to access and change the modules as required.

-

Effortless Module Installation: Installing a new or replacement EEPROM module is equally hassle-free. The module can simply be placed onto the socket and pushed into place until it is properly seated. This ease of module installation ensures that upgrades or replacements can be carried out quickly and accurately, minimizing system downtime during maintenance activities.

Technical Parameters:DS3800HVDB1K1G

- EEPROM Module Specifications:

- Number of Modules: It is equipped with multiple Electrically Erasable Programmable Read-Only Memory (EEPROM) modules. While the exact number may vary depending on the specific model or configuration, these modules serve as the primary storage for the board's firmware and other essential code.

- Capacity per Module: Each EEPROM module typically has a specific storage capacity, which could range from a few kilobytes to several megabytes, depending on the design. This capacity determines the amount of firmware, control algorithms, and other data that can be stored. For example, a common capacity might be in the range of 128 KB to 512 KB per module, allowing for a significant amount of code to be held when multiple modules are present.

- Access Time: The EEPROM modules have a defined access time, which indicates how quickly data can be read from or written to the memory. This access time is usually measured in nanoseconds or microseconds and is crucial for ensuring efficient operation when the board is retrieving or updating its firmware or other stored information. An access time in the range of tens to hundreds of nanoseconds is typical for modern EEPROMs used in such applications, enabling fast processing of the stored code.

-

Output Signal Types:

- Analog Video Signals: The board is capable of generating analog video signals, such as Composite Video (CVBS), which combines the luminance (brightness), chrominance (color), and synchronization information into a single signal. It may also support other analog formats like Component Video (YUV or RGB component signals), which separate the color and brightness information into different channels for higher quality video transmission. These analog signals are useful for connecting to a variety of older or legacy display devices that rely on analog inputs.

- Digital Video Signals: In addition to analog signals, the DS3800HVDB1K1G can likely produce digital video signals. This could include formats like HDMI (High-Definition Multimedia Interface), DisplayPort, or LVDS (Low-Voltage Differential Signaling). The ability to output digital signals allows for compatibility with modern high-definition displays and monitors, providing sharp and clear visual content. For example, HDMI can support various resolutions up to Ultra High Definition (UHD) 4K or even higher, depending on the version and capabilities of the board.

-

Video Signal Resolution:

- Supported Resolutions: The board can support a range of video resolutions. For analog signals, it may cover standard-definition resolutions like 720 x 480 (NTSC) or 720 x 576 (PAL), as well as some higher resolutions depending on the specific capabilities of the analog output circuitry. For digital video signals, it can typically handle a wide range of resolutions from standard HD (1280 x 720) to Full HD (1920 x 1080), and in many cases, extend to higher resolutions like 4K (3840 x 2160) or even 8K (7680 x 4320), depending on the display interfaces it supports and the overall design of the board.

- Scaling and Interpolation: The board may incorporate features for video signal scaling and interpolation. This means that it can adjust the input video source to match the native resolution of the connected display device. For example, if the input video has a lower resolution than the display's native resolution, the board can scale it up using interpolation algorithms to fill the entire screen while maintaining acceptable image quality. Conversely, if the input video is in a higher resolution, it can downscale it to fit the display without losing too much detail.

-

Video Signal Timing:

- Refresh Rates: The DS3800HVDB1K1G supports various refresh rates for the video signals it generates. In the case of analog video, common refresh rates like 50 Hz (for PAL systems) or 60 Hz (for NTSC systems) are typically supported, and for digital video, it can handle a wider range including higher refresh rates like 120 Hz, 144 Hz, or even 240 Hz, depending on the display technology and the board's capabilities. These refresh rates are crucial for smooth and flicker-free visual display, especially when showing dynamic content such as real-time industrial process monitoring or video playback.

- Synchronization: The board ensures proper synchronization of the video signals, including horizontal and vertical synchronization. This synchronization is essential for aligning the video frames correctly on the display screen to create a stable and coherent visual image. It follows industry-standard synchronization protocols for each video signal format it supports to ensure compatibility with different display devices.

-

Connector Types:

- Modular Connector: At one end, it has a modular connector that serves as the main interface for connecting to other components within the system. This connector is likely designed to carry multiple signals, including power, data, and control signals, and is usually standardized to ensure compatibility with other boards or devices in the GE Speedtronic system or other relevant industrial setups.

- 20-Pin Connector: There is also a 20-pin connector located between the retaining bars on the board. This connector provides additional connection points for specific functions, such as interfacing with external monitors, display devices, or other components that require video signal input or related data exchange. The pin configuration of this connector is designed to support specific signal types and functions according to the board's design requirements.

-

Digital I/O Channels:

- Number of Digital Inputs: The board may have a specific number of digital input channels, which can receive binary signals from external devices. The exact count could vary, but these inputs are useful for receiving status information or commands from other components in the system. For example, it could receive signals indicating the power-on status of related equipment, the activation of certain functions, or the detection of specific events.

- Number of Digital Outputs: Similarly, there are digital output channels available. These can be used to send control signals to other devices, such as activating indicator lights, relays, or other digital components within the system. The number of digital outputs is configured to meet the requirements of the application for controlling various external elements based on the board's operation and the functions it performs.

- Supported Communication Protocols:

- Ethernet-Based Protocols: The DS3800HVDB1K1G likely supports Ethernet-based communication protocols like EtherNet/IP or TCP/IP. This enables it to communicate with other devices on an Ethernet network, facilitating data exchange with other components in the industrial control system, Supervisory Control and Data Acquisition (SCADA) systems, or enterprise-level management platforms. The ability to use these protocols allows for remote monitoring, configuration, and control of the board and its associated functions.

- Serial Protocols: It may also support serial communication protocols such as RS-232 or RS-485. These serial interfaces are useful for connecting to legacy devices or for applications where a simple and reliable point-to-point communication is required. For example, it can communicate with older sensors or controllers that use serial communication for data transfer, ensuring compatibility and integration within a mixed-technology system.

- Input Voltage Range: The board operates within a specific input voltage range, which is typically designed to be compatible with common industrial power supplies. This range could be something like 18V DC to 32V DC, for example, allowing it to receive power reliably from different power sources, including those with some voltage fluctuations or those used in specific industrial environments like power plants, factories, or offshore installations.

- Power Consumption: The power consumption of the DS3800HVDB1K1G depends on various factors such as the load on its video signal generation, the activity level of its communication interfaces, and the power requirements of any internal components. Under normal operating conditions, it might consume a few watts to tens of watts of power. This power consumption is optimized to balance its functionality with energy efficiency, minimizing heat generation and ensuring reliable operation within its specified temperature range.

- Operating Temperature: The board is designed to function within a specific temperature range, which is usually quite wide to accommodate various industrial environments. A typical operating temperature range could be from -33°C to 56°C. This broad tolerance enables it to operate reliably in both cold outdoor settings (such as in power substations in colder regions) and hot and humid indoor environments (like in factories where industrial processes generate heat).

- Response Time: In terms of its response time for generating video signals or reacting to input signals and commands, it is designed to meet the requirements of real-time applications. For example, when there is a change in the input data related to the information to be displayed (such as a sudden change in a monitored industrial parameter), the board can quickly update the video signal to reflect this change on the display within milliseconds. This fast response time is crucial for applications where timely visual feedback is essential, such as in industrial control rooms or in systems that require immediate visual indication of events.

Applications:DS3800HVDB1K1G

-

Flight Deck Displays: In aircraft, the DS3800HVDB1K1G can be integrated into the flight deck display systems. It can generate video signals for primary flight displays (PFDs), showing information like airspeed, altitude, attitude, and navigation data. It can also drive multi-function displays (MFDs) that present additional information such as weather radar images, engine parameters, and flight plan details. Pilots rely on these clear and accurate visual displays to make critical decisions during flight, ensuring the safety and efficiency of the aircraft's journey.

-

Aircraft Maintenance and Ground Support: On the ground, during aircraft maintenance and inspection, the video driver board can be used to display diagnostic information from various onboard systems. For example, it can show the output of sensors monitoring the health of the aircraft's landing gear, hydraulic systems, or avionics components. Maintenance technicians can use these visual cues to quickly identify and troubleshoot any potential issues, facilitating efficient maintenance procedures and reducing aircraft downtime.

-

Medical Imaging: In medical facilities, the DS3800HVDB1K1G is valuable for driving the display interfaces of imaging devices such as CT scanners, MRI machines, and ultrasound equipment. It can take the raw image data generated by these devices and convert it into high-quality video signals for display on monitors. This enables medical professionals to clearly view the scanned images, make accurate diagnoses, and plan appropriate treatment strategies. For example, in a radiology department, it ensures that the detailed anatomical images obtained from a CT scan are presented with the right contrast, resolution, and color accuracy for proper interpretation.

-

Patient Monitoring Systems: The board can also be used in patient monitoring systems to display vital signs such as heart rate, blood pressure, oxygen saturation, and electrocardiogram (ECG) waveforms. In intensive care units or operating rooms, where multiple parameters need to be monitored simultaneously, the DS3800HVDB1K1G can generate video signals to display this information in a clear and organized manner on bedside monitors or central monitoring stations. This allows medical staff to keep a close eye on patients' conditions and respond promptly to any changes.

-

Command and Control Centers: In military command and control centers, the video driver board can display crucial information related to battlefield situations, including the location of friendly and enemy forces, real-time intelligence feeds, and the status of various military assets such as vehicles, aircraft, and ships. It can integrate with different surveillance systems, radars, and communication networks to present a comprehensive visual overview for commanders to make strategic decisions.

-

Weapon Systems: For military weapon systems, the DS3800HVDB1K1G can be used to display targeting information, weapon status, and firing solutions. For example, in a tank's fire control system, it can show the gunner the target's position, range, and other relevant data on the display, enabling accurate aiming and firing. In naval vessels, it can display information related to the ship's weapon systems, sonar readings, and navigation data for effective combat operations.

-

Railway Control Rooms: In railway systems, the board can be used to display information about train schedules, the position of trains on the tracks, and the status of railway infrastructure such as signals, switches, and track conditions. Operators in the control room rely on these visual displays to manage train movements, ensure safety, and prevent collisions or delays.

-

Vehicle Telematics and Fleet Management: In the commercial transportation sector, the DS3800HVDB1K1G can be integrated into vehicle telematics systems to display information like vehicle speed, engine performance, fuel consumption, and location data. Fleet managers can use this visual information to monitor their vehicles remotely, optimize routes, schedule maintenance, and improve overall fleet efficiency.

-

Broadcast Studios: In television and radio broadcast studios, the video driver board can be used to display video feeds from cameras, graphics, and other sources for on-air production. It can also be integrated into video switchers and production consoles to manage and display the multiple video signals used in creating live broadcasts or recorded shows.

-

Digital Signage: In public spaces, malls, airports, and other locations, the board can be used for digital signage applications. It can generate video signals to display advertisements, informational messages, and wayfinding content on large display screens, providing visual communication to the public.

Customization:DS3800HVDB1K1G

-

I/O Customization:

-

Connector Types and Pinouts: Depending on the specific connections needed in an application, the hardware can be customized in terms of the types of connectors and their pin configurations. For example, if a particular industrial setup requires a specific type of video connector that is not standard on the DS3800HVDB1K1G, the board can be modified with an adapter or a custom connector interface. Additionally, the pinouts of the existing connectors can be adjusted to match the signal requirements of the connected devices. In a military application where secure and specialized connectors are used, the board can be retrofitted with the appropriate connectors to ensure compatibility with the overall system's cabling infrastructure.

-

I/O Expansion: For applications that require more input or output channels than the standard configuration of the board provides, external I/O expansion modules can be added. For instance, if there is a need to connect additional digital sensors or control more external devices based on the video display status, extra digital I/O ports can be integrated through expansion modules. This allows for greater flexibility in interfacing with a wider range of components in the system.

-

Power Input Customization: In some industrial settings with unique power supply characteristics, the power input of the DS3800HVDB1K1G can be customized. For example, in an offshore oil platform where the power supply may have significant voltage fluctuations and harmonic distortions due to the complex electrical infrastructure and the use of generators, custom power conditioning modules like DC-DC converters with advanced voltage regulation and filtering capabilities can be added. These ensure that the board receives stable and clean power, safeguarding it from power surges and maintaining its reliable operation. In a remote solar power generation site where the power generated by solar panels is stored in batteries and the voltage levels vary depending on the battery state of charge, similar power input customization can be done to make the board compatible with the available power supply and operate optimally under those conditions.

- Enclosure and Protection Customization:

-

Harsh Environment Adaptation: In extremely harsh industrial environments, such as those with high levels of dust, humidity, chemical exposure, or extreme temperatures, the physical enclosure of the DS3800HVDB1K1G can be customized. In a desert-based power plant where dust storms are common, the enclosure can be designed with enhanced dust-proof features like high-efficiency air filters, sealed gaskets, and a rugged outer casing to keep the internal components clean. Special coatings can be applied to the board and its components to protect against the abrasive effects of dust particles. In a chemical processing plant where there is a risk of chemical splashes and fumes, the enclosure can be made from materials resistant to chemical corrosion, such as stainless steel or specialized plastic composites. It can also be sealed to prevent any harmful substances from reaching the internal components, and additional ventilation systems can be incorporated to manage any potentially explosive or harmful gas build-up.

-

Thermal Management: Depending on the ambient temperature conditions of the industrial setting, custom thermal management solutions can be incorporated. In a facility located in a hot climate where the board might be exposed to high temperatures for extended periods, additional heat sinks, cooling fans, or even liquid cooling systems (if applicable) can be integrated into the enclosure to maintain the device within its optimal operating temperature range. In cold environments like Arctic oil and gas exploration sites, heating elements or insulation can be added to the enclosure to ensure that the DS3800HVDB1K1G starts up and operates reliably even in freezing temperatures.

- Compliance Customization:

-

Nuclear Power Plant Requirements: In nuclear power plants, which have extremely strict safety and regulatory standards, the DS3800HVDB1K1G can be customized to meet these specific demands. This might involve using radiation-hardened materials for the board's components, undergoing specialized testing and certification processes to ensure reliability under nuclear conditions, and implementing redundant or fail-safe features. For example, redundant power supplies and multiple layers of error detection and correction in the software can be incorporated to comply with the high safety requirements of the industry. Additionally, enhanced electromagnetic shielding can be applied to protect against any potential interference that could affect the board's operation in the nuclear environment.

-

Aerospace and Aviation Standards: In aerospace applications, there are strict regulations regarding vibration tolerance, electromagnetic compatibility (EMC), and reliability due to the critical nature of aircraft operations. The DS3800HVDB1K1G can be customized to meet these requirements. For example, it might need to be modified to have enhanced vibration isolation features, such as using specialized shock mounts and damping materials. The board can also be modified with better protection against electromagnetic interference, including shielding and filtering measures to ensure reliable operation during flight. In an aircraft auxiliary power unit (APU) application, the DS3800HVDB1K1G would need to comply with strict aviation standards for quality and performance to ensure the safety and efficiency of the APU and associated systems. This could involve using lightweight and high-reliability components, as well as undergoing rigorous testing and certification procedures specific to the aerospace industry.

Support and Services:DS3800HVDB1K1G

Our Product Technical Support and Services team is dedicated to helping you with any issues or questions you may have regarding our product. We offer a range of services, including:

- 24/7 customer support

- Online knowledge base and FAQs

- Product manuals and documentation

- Remote troubleshooting and diagnostics

- In-person technical support and training

We pride ourselves on our fast and efficient response times, and our team of experts is always available to assist you with any technical issues you may encounter. Our goal is to ensure that you have the best possible experience with our product and that your business operations run smoothly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!