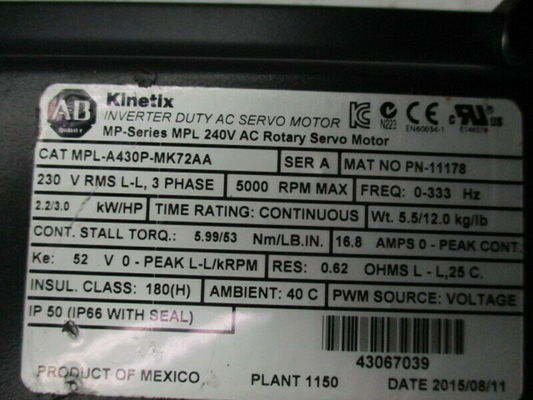

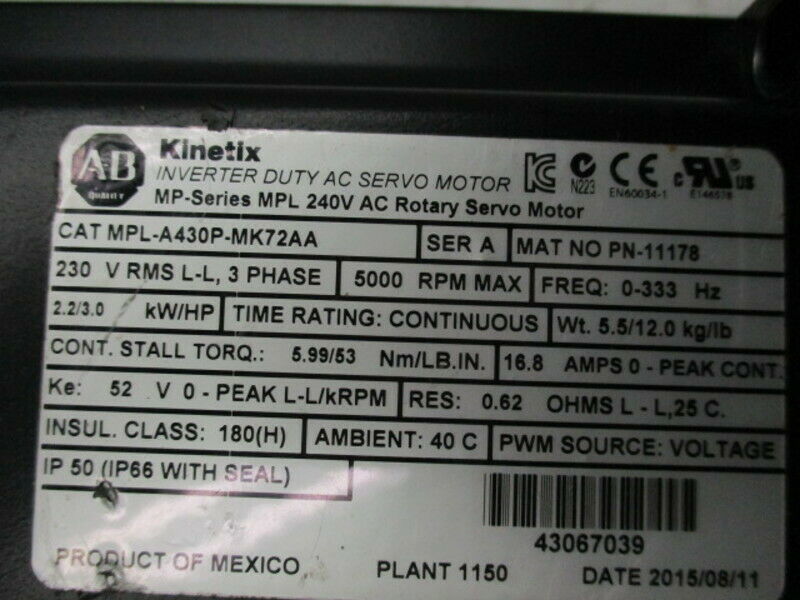

Product Description:MPL-A430P-MK72AA

The Allen-Bradley MPL-A430P-MK72AA is a high-performance AC servo motor from Allen-Bradley’s MPL series, designed to deliver high torque, precision motion control, and reliable performance in a wide variety of demanding industrial applications. This motor is specifically engineered to handle applications requiring high speed, dynamic response, and long-term durability.

Built to integrate seamlessly with Allen-Bradley Kinetix and other motion control systems, the MPL-A430P-MK72AA is widely used in industries such as robotics, automated manufacturing, material handling, and CNC machinery, where precision and efficiency are critical. It provides continuous, smooth, and precise motion, ensuring accurate position control, speed regulation, and torque management for complex motion systems.

The MPL-A430P-MK72AA features advanced feedback systems (such as encoders or resolvers) for precise real-time position and speed tracking. It is also designed for easy integration with Allen-Bradley drives, offering a closed-loop control solution that helps optimize system performance and minimize energy consumption.

This servo motor’s compact design, high torque-to-weight ratio, and rugged construction make it a versatile solution for a variety of applications, from high-speed robotics to precision CNC and automated assembly lines.

Features:MPL-A430P-MK72AA

-

High Torque and Power Output:

The motor provides robust torque for demanding applications, delivering high continuous torque while maintaining smooth motion and precision under varying load conditions.

-

Precision Motion Control:

With integrated feedback systems (e.g., encoders), the motor offers highly accurate position, speed, and torque control for critical motion applications.

-

Energy Efficiency:

Designed for high efficiency, the MPL-A430P-MK72AA minimizes energy consumption, which contributes to reduced operational costs, especially in applications with high-duty cycles.

-

Rugged and Durable Design:

Built for continuous-duty operation, the motor features durable construction to withstand high-vibration and harsh environments. Its long lifespan minimizes maintenance and downtime.

-

Compact Size and Lightweight:

With a compact design and high torque-to-weight ratio, it is ideal for applications with space constraints or where low weight is critical.

-

Seamless Integration:

The motor integrates easily with Allen-Bradley Kinetix and 1326-series servo drives, providing a complete, high-performance motion control system for a wide range of automation systems.

-

Versatile Applications:

Ideal for robotics, CNC machines, automated assembly lines, material handling, and printing machines, it excels in applications that require high precision, fast dynamic response, and continuous performance.

Technical Parameters:MPL-A430P-MK72AA

Applications:MPL-A430P-MK72AA

- Robotics: For precise motion control in robotic arms, pick-and-place systems, and automated assembly systems.

- CNC Machinery: In CNC mills, lathes, and other machine tools requiring accurate position control and smooth operation.

- Material Handling: In automated conveyor systems, sorting machines, and packaging lines.

- Printing and Textile Manufacturing: For high-speed printing and textile production systems requiring accurate speed regulation and precise motion.

- Medical Equipment: In systems like robotic surgery, imaging devices, and medical diagnostics requiring smooth motion and high precision.

Customization:MPL-A430P-MK72AA

-

Voltage Range:

While the standard voltage for the MPL-A430P-MK72AA is 230 VAC, it can be customized for other voltage ratings, including:

- 380-480 VAC (for higher power applications).

- 110/120 VAC (for lower voltage systems).

-

Power Ratings:

Custom configurations can be made to the power output based on the required torque and speed characteristics of your application. Options are available within the typical range of 3.0 kW to 7.5 kW, depending on the needs of the specific system.

- Shaft Configuration:

- The motor comes with a keyed shaft by default, but smooth shaft versions are available for systems that require specialized coupling or mounting.

- Custom shaft lengths and diameters can be selected to fit specific mechanical systems or coupling needs.

- Mounting Options:

- The MPL-A430P-MK72AA motor typically comes with NEMA mounting standards (e.g., NEMA 56 or NEMA 143 frame), but custom flange sizes and mounting patterns can be provided for specific integration needs.

-

Encoder Type:

The MPL-A430P-MK72AA motor can be customized with different encoder types to provide the appropriate feedback for your motion control system:

- Incremental encoders (e.g., 1024 PPR, 2048 PPR).

- Absolute encoders for higher accuracy in position tracking.

-

Encoder Resolution:

- Custom encoder resolutions can be selected based on the precision needed in your application. Higher resolution encoders will offer more precise feedback and are ideal for high-accuracy applications.

-

Feedback Voltage:

- Standard 5V or 12V feedback, but custom voltage options may be available to match specific system requirements.

-

IP Enclosure Rating:

While the standard model has an IP20 protection rating (suitable for indoor applications), it can be customized to meet higher IP ratings for more demanding environments:

- IP54: Protection against dust and splashing water, suitable for general industrial environments.

- IP65: Fully sealed, dust-tight, and resistant to water jets, ideal for harsh, wet, or outdoor environments.

- IP67: Protection against submersion in water (up to 1 meter depth), suitable for extreme conditions.

-

Corrosion Protection:

Custom corrosion-resistant coatings can be applied for use in harsh or chemically aggressive environments (e.g., food processing or marine applications).

- Standard Cooling:

The standard fan cooling is suitable for most general applications, but custom cooling systems can be designed for high-temperature environments or applications with low airflow:

- Liquid cooling: For applications requiring high heat dissipation or operation in extreme temperatures.

- Forced air cooling: Higher performance fans or custom ventilation systems can be specified for specific airflow requirements.

-

Operating Temperature Range:

The MPL-A430P-MK72AA motor can be customized to operate in extreme temperature ranges:

- Extended low-temperature operation: Motors can be specified for environments down to -20°C or even -40°C.

- High-temperature operation: Customized for environments up to 60°C, 70°C, or even 80°C, with Class H insulation for higher thermal endurance.

-

Insulation Class:

- While the motor typically comes with Class F insulation (155°C), it can be customized with Class H (180°C) insulation for higher operational temperatures or long-term use in hot environments.

-

Custom Windings:

If you have specific torque and speed characteristics that need to be met, the motor can be customized with different winding configurations to adjust the torque output, speed range, and efficiency.

- This option allows for customization based on dynamic response, starting torque, or speed control needs in specific applications.

-

Torque Characteristics:

The motor’s torque-to-speed curve can be tailored to suit specific application needs, such as high starting torque or constant torque across a wide speed range.

-

Control Interface:

The motor can be customized with various communication protocols and control interfaces to work with your existing control systems:

- Ethernet/IP, CANopen, SERCOS, Modbus for high-speed digital communication and integration with various motion controllers.

- Analog input/output or digital I/O options can be added if your system requires direct control over speed, position, or torque.

-

Advanced Control Features:

Custom motion control algorithms (e.g., for torque ripple reduction, speed regulation, or positioning) can be implemented for specialized motion control applications like high-precision robotics or synchronous applications.

-

Global Certifications:

The motor can be customized to meet various global certifications for different industries:

- CE, UL, CSA, RoHS, ISO, and other regional or international standards for safety, quality, and environmental compliance.

-

Hazardous Location Options:

If your application is in a hazardous environment (such as explosive atmospheres), the motor can be modified to meet ATEX, IECEx, or UL Hazardous Location certifications, ensuring safe operation in these conditions.

-

Custom Mounting Brackets:

If the motor needs to be installed in a unique mechanical system, custom mounting brackets, flanges, or coupling adapters can be provided.

-

Noise and Vibration Reduction:

For applications requiring low-noise operation (such as medical devices, audio equipment, or laboratory systems), the motor can be modified with low-vibration components or acoustic dampening features.

Support and Services:MPL-A430P-MK72AA

Our Industrial Servo Drives product comes with comprehensive technical support and services to ensure reliable and efficient operation. Our team of experienced technicians are available to assist with any technical issues or questions that may arise during installation, commissioning, and operation.

We provide a range of services to help you get the most out of your servo drives, including:

- On-site installation and commissioning support

- Remote technical support via phone or email

- Regular maintenance and training programs

- Repair and replacement services for faulty or damaged equipment

- Customization services to meet specific application requirements

Our technical support and services are designed to minimize downtime, increase productivity, and ensure the long-term reliability of your servo drives. Contact us to learn more about how we can support your industrial automation needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!