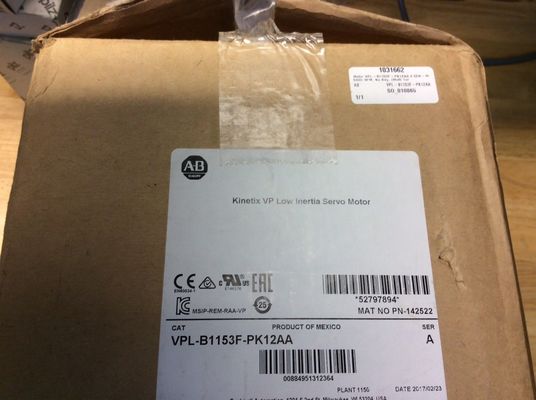

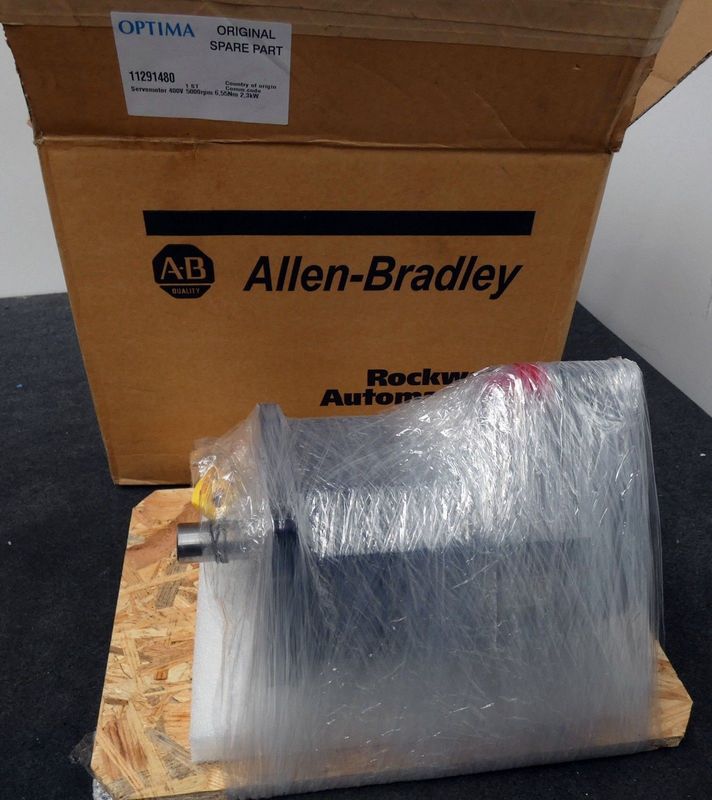

Product Description:VPL-B1153F-PK12AA

The VPL-B1153F-PK12AA is a model within the VPL series, designed for general-purpose motor control in industrial environments. It combines advanced motor control capabilities, energy efficiency, and reliable protection features, making it suitable for a wide range of applications. Below is an in-depth look at the key characteristics, features, technical parameters, and customization options for the VPL-B1153F-PK12AA.

Features:VPL-B1153F-PK12AA

-

Compact and Flexible Design:

- The VPL-B1153F-PK12AA has a compact form factor, making it ideal for applications where space is limited. It is designed for easy panel mounting and can be installed in both industrial environments and OEM machinery.

-

Variable Frequency Control:

- This VFD offers precise control over motor speed and torque by adjusting the frequency of the AC power supplied to the motor. The ability to adjust frequency allows for energy savings and optimized performance in applications with varying load conditions.

-

Energy Efficiency:

- By controlling the motor speed and optimizing power usage, the VPL series contributes to significant energy savings compared to traditional fixed-speed drives. Energy efficiency is especially beneficial in pumping systems, HVAC systems, and other processes with variable load demands.

-

Built-in Motor Protection:

- The VPL-B1153F-PK12AA provides integrated motor protection features, such as:

- Overload protection.

- Overcurrent protection.

- Overvoltage and undervoltage protection.

- Short circuit protection.

- Overtemperature protection.

- These features ensure that both the motor and the drive are well-protected against common electrical faults.

-

User-Friendly Interface:

- The VFD comes with a built-in keypad and display for easy configuration, monitoring, and operation. It can also be connected to external HMI panels for more advanced user interaction.

-

PID Control Functionality:

- Many models in the VPL series, including the VPL-B1153F-PK12AA, feature PID (Proportional-Integral-Derivative) control, which ensures precise control of processes requiring constant parameters, such as pressure, temperature, or flow.

-

Flexible Communication Protocols:

- The VPL-B1153F-PK12AA supports a range of communication protocols for integration into automation systems, including:

- Modbus RTU (serial communication).

- Ethernet/IP for industrial network integration.

- DeviceNet (in certain models).

- CANopen (depending on configuration).

- These options allow the VFD to be easily connected to PLCs, HMIs, and other industrial devices for remote monitoring and control.

-

Advanced Braking Control:

- The VFD provides the option for dynamic braking or regenerative braking, which is ideal for applications requiring fast deceleration, such as conveyors, elevators, or hoists. This functionality recovers energy during braking and feeds it back into the grid, improving efficiency.

-

Customizable Ramp-Up and Ramp-Down Times:

- The acceleration and deceleration times can be adjusted to suit the application. Smooth starts and stops reduce mechanical stress and extend the life of the motor and equipment.

Technical Parameters:VPL-B1153F-PK12AA

| Model Number |

VPL-B1153F-PK12AA |

| Power Rating |

Typically 1.5 kW (2 HP) |

| Input Voltage |

200V to 240V AC (single-phase) |

| Output Voltage |

Variable, depends on input frequency |

| Frequency Range |

0 – 400 Hz |

| Control Method |

V/f Control (Voltage/Frequency) |

| Motor Type Supported |

Induction Motors |

| Max Output Current |

Approximately 8.3 A |

| Speed Control Accuracy |

±0.5% (depending on load conditions) |

| Communication Protocols |

Modbus RTU, Ethernet/IP (depending on model) |

| Overload Protection |

120% for 60 seconds (adjustable) |

| Ambient Temperature Range |

-10°C to +40°C |

| Storage Temperature Range |

-20°C to +60°C |

| Humidity Range |

5% to 95% RH, non-condensing |

| Mounting Type |

DIN rail or wall-mounted |

| Protection Class |

IP20 (standard, may vary depending on configuration) |

|

Applications:VPL-B1153F-PK12AA

-

HVAC Systems:

- The VFD is commonly used to control air handling units (AHUs), fans, and pumps in HVAC systems, offering precise control over airflow and temperature, as well as energy savings during low-load conditions.

-

Water and Wastewater Treatment:

- In water treatment plants, the VPL-B1153F-PK12AA can control pumps for filtration and circulation processes, ensuring efficient energy use and stable performance in variable-load situations.

-

Material Handling:

- The VFD can be used to control conveyors, elevators, and lifts, ensuring smooth acceleration and deceleration, minimizing mechanical stress, and optimizing throughput.

-

Pumps and Compressors:

- Pumps and air compressors in various industrial applications benefit from the VPL’s ability to control speed in response to changing demand, ensuring optimal operation and energy efficiency.

-

Manufacturing and Process Control:

- The VPL series is ideal for automated production lines and robotic applications where precise speed control and feedback are necessary. It ensures smooth operation of CNC machines, machinery, and robotic arms.

-

Agriculture:

- The VFD can be used in irrigation systems, feed mills, and grain handling equipment, where precise motor control helps improve efficiency and optimize operations.

Customization:VPL-B1153F-PK12AA

-

Speed Control Adjustments:

- The speed range and acceleration/deceleration rates can be customized based on the application’s needs (e.g., linear ramp, S-curve).

-

PID Control Customization:

- PID parameters (Proportional, Integral, and Derivative gains) can be adjusted to maintain a constant process variable, such as flow, pressure, or temperature.

-

I/O Configuration:

- Digital and analog inputs/outputs can be customized for external control, feedback signals, or integration with other devices, such as PLC or HMI.

-

Communication Protocol Selection:

- Depending on your system, the VPL-B1153F-PK12AA can be configured for communication using Modbus RTU, Ethernet/IP, or other protocols to integrate seamlessly into networked control systems.

-

Motor Protection Settings:

- Customize settings for overload, overvoltage, and undervoltage protection to tailor the drive’s protection mechanisms to specific motor characteristics or application needs.

-

Regenerative Braking:

- Dynamic braking or regenerative braking functionality can be customized to suit applications that require rapid deceleration or energy recovery.

-

User Interface Configuration:

- Customizing the HMI (Human-Machine Interface) or keypad to display specific data or parameters, and setting up password protection or access control for sensitive settings.

Support and Services:VPL-B1153F-PK12AA

Our Industrial Servo Drives come with comprehensive technical support and services to ensure optimal performance and reliability. Our team of experts is available to provide assistance with installation, configuration, and troubleshooting. We also offer training programs to help customers maximize the potential of their servo drives.

Our services include repair and maintenance, as well as customized engineering solutions to meet specific application needs. We are committed to providing timely and efficient support to minimize downtime and ensure uninterrupted operation of our customers' systems.

Additionally, we offer a range of accessories and replacement parts to enhance the functionality and extend the lifespan of our servo drives. Contact us for more information on our technical support and services.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!