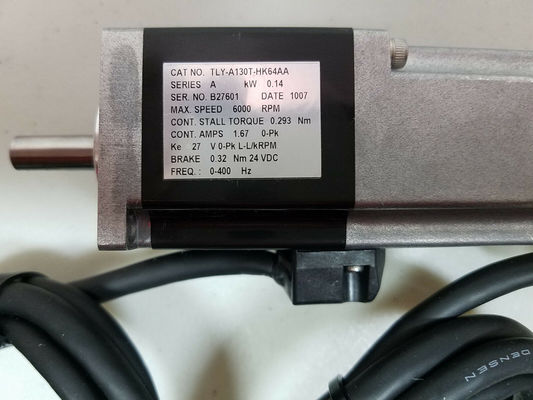

Product Description:TLY-A130T-HK64AA

The Allen-Bradley TLY-A130T-HK64AA is likely a thermal overload relay designed for motor protection. It would typically be used to protect motors from overheating due to excess current, ensuring safe operation and extending the lifespan of motor-driven systems. The relay is likely part of the TLY series, which is known for offering adjustable trip settings, compact design, and reliable motor protection in industrial automation setups.

Features:TLY-A130T-HK64AA

-

Adjustable Overload Settings:

- The TLY series typically allows for adjustment of the overload protection to suit various motor sizes and applications. This can be critical for optimizing motor protection based on the specific load characteristics.

-

Thermal Overload Protection:

- Protects motors from overheating due to excessive current or prolonged overcurrent conditions. This helps prevent motor failure caused by temperature rise, improving the reliability and lifespan of the motor.

-

Manual and Automatic Reset Options:

- Many models, including those in the TLY series, offer manual or automatic reset options. After a motor trips due to an overload, the relay can either be reset manually by an operator or automatically after a predetermined cool-down period.

-

Compact and Space-Saving Design:

- The TLY relays are designed to be compact, making them suitable for applications where space is limited.

-

Wide Current Range:

- The TLY series generally offers a broad range of current ratings, which means it can be used with a variety of motor sizes, from small motors to larger, high-power systems.

-

Integral Trip Indication:

- These relays typically feature a trip indicator that clearly shows when the motor has been disconnected due to an overload, helping operators easily identify issues.

-

Temperature Compensation:

- Advanced thermal overload relays like those in the TLY series often have temperature compensation features to ensure reliable protection under varying ambient temperatures. This ensures consistent performance regardless of the environmental conditions.

-

Coil and Contact Protection:

- Designed to offer protection for both the relay's coil and its contact components. This reduces wear on the system and minimizes the chances of relay failure.

-

Easy Integration with Contactor Systems:

- The TLY overload relays are typically designed to be compatible with Allen-Bradley contactors, ensuring seamless integration into motor control circuits, making it easier for engineers and operators to design and implement motor protection systems.

-

High Durability and Reliability:

- These relays are known for their robust construction and reliable performance in harsh industrial environments, making them suitable for a wide variety of industrial applications.

Technical Parameters:TLY-A130T-HK64AA

-

Current Rating:

- The TLY-A130T-HK64AA model likely falls within a specific current range based on its intended application. Typically, TLY series overload relays are available in current ratings ranging from 1.0 A to 32.0 A or higher, depending on the model.

- The 130T in the part number suggests a current rating of 13.0 A (often adjustable).

-

Trip Class:

- The TLY series generally features a trip class rating that determines the time-to-trip characteristics. Common classes include Class 10 (trips within 10 seconds for overload conditions) or Class 20 (for longer time delays).

- The TLY-A130T-HK64AA might feature a Class 10 or Class 20 characteristic depending on motor protection needs.

-

Adjustable Overload Setting:

- Overload settings are typically adjustable within a specified range to suit the connected motor’s rated current. For example, the 13.0 A range might allow adjustments from 10 A to 16 A or similar, depending on the model.

-

Voltage Rating:

- Overload relays in this series typically handle standard AC control voltages, such as 200V-600V AC. The exact voltage ratings would depend on the application and the specific contactor system used.

-

Reset Type:

- Manual or automatic reset options are typical, allowing the relay to be reset after it trips due to an overload.

- Manual reset may require an operator to physically reset the relay, while automatic reset happens after a cool-down period.

-

Ambient Temperature Range:

- The TLY series generally operates in an ambient temperature range of -20°C to +60°C (-4°F to 140°F). The exact temperature range can vary depending on the model and specific operating conditions.

-

Contact Type:

- These relays generally feature SPDT (Single Pole, Double Throw) or DPDT (Double Pole, Double Throw) contacts, allowing for proper control of motor circuits.

-

Indication Features:

- Trip Indication: A visual trip indicator that shows if the relay has tripped due to overload.

- Overload Reset Button: Allows for manual resetting of the overload relay after a trip.

-

Conductor Size:

- Terminal block connection is often used, with appropriate wire sizes ranging from 14 AWG to 6 AWG (depending on the current rating).

-

Mounting Type:

- These relays are typically designed for DIN rail mounting or screw terminal mounting, making them easy to integrate into existing control panels.

-

Protection Features:

- The TLY series includes features like thermal memory, which remembers the motor’s thermal state during a trip and ensures safe startup after a cool-down period.

- Thermal overload protection adjusts to the motor's actual load conditions and ensures proper protection from sustained overcurrent situations.

-

Short-Circuit Protection:

- The TLY relays are often used in conjunction with circuit breakers or fuses to provide comprehensive short-circuit and overload protection.

Applications:TLY-A130T-HK64AA

-

Motor Protection in Industrial Equipment:

- General Motor Control: Used in motor control circuits to protect electric motors from damage caused by thermal overload, ensuring safe operation in machinery like conveyors, pumps, compressors, and HVAC systems.

- Pump Motors: Protects motors that drive pumps in applications such as water treatment, chemical processing, and HVAC (Heating, Ventilation, and Air Conditioning).

- Fan Motors: Often used in fan applications in industrial environments to protect against thermal overload.

- Conveyor Systems: In automated manufacturing, material handling, or packaging systems, the relay protects motors that drive conveyor belts, which can be subjected to varying load conditions.

-

HVAC Systems:

- Heating, Ventilation, and Air Conditioning: In HVAC applications, where large motors drive compressors, blowers, and fans, thermal overload relays like the TLY series are essential for ensuring that these systems operate reliably and efficiently.

- Air Handling Units (AHUs): Protects motors in air handling systems used in commercial buildings or industrial facilities.

-

Pumps in Water and Wastewater Systems:

- Water Pumps: Protects motors that drive water pumps in various industries such as municipal water supply, irrigation systems, and water treatment plants.

- Sewage Pumps: Similarly, overload relays are used to protect sewage and wastewater pumping systems, where long operation hours or unexpected changes in flow can lead to overload conditions.

-

Manufacturing Equipment:

- Machine Tools: In industrial machining and manufacturing, motors are often subjected to varying loads. Overload relays prevent damage to motors in equipment like lathes, drills, and CNC (Computer Numerical Control) machines.

- Material Handling: For machinery that moves materials in factories, thermal overload relays are crucial to ensuring the motor does not overheat due to sustained or unexpected load conditions.

-

Compressor Protection:

- Air Compressors: Protects the motors in air compressors used in various industrial and commercial applications, including pneumatic tools, production lines, and construction machinery.

- Refrigeration Systems: Protects compressor motors in refrigeration and cooling units, which may be exposed to frequent on-off cycles and fluctuating loads.

-

Industrial Automation:

- Conveyor Belts: Protects motors in automated conveyor systems found in assembly lines, material handling, packaging, and distribution centers.

- Robotics: In industrial robotic systems, overload relays help protect motors that control robotic arms or automated processes, ensuring smooth and safe operation during production.

-

Mining and Heavy Equipment:

- Mining Equipment: Overload relays are used to protect large motors in mining operations that drive conveyors, crushers, and drills, where the load on motors can be unpredictable or high.

- Heavy Machinery: Motors that drive large equipment like cranes, hoists, and winches are protected using overload relays in harsh, high-vibration environments.

-

Agricultural and Irrigation Systems:

- Irrigation Pumps: Protects motors in agricultural pumps that move water for irrigation. These systems are often exposed to varying loads and demands.

- Farm Equipment: Overload relays are used in farm machinery, including grain elevators and feed mills, where motors need protection from thermal overload conditions.

-

Renewable Energy Applications:

- Wind Turbine Motors: Protects motors in wind turbines that drive generators and other mechanical systems.

- Solar Pumping Systems: In solar-powered water pumping systems, the overload relay ensures the pump motor is protected from overheating during periods of high load or during startup.

-

Elevators and Escalators:

- Motors that drive elevators, escalators, and other vertical transportation systems benefit from thermal overload protection to prevent motor damage due to prolonged overcurrent or stuck conditions.

-

Food and Beverage Processing:

- Food Conveyors: Protects motors in conveyor systems used in food processing and packaging lines, where continuous operation can result in overload conditions.

- Blending and Mixing Equipment: In food processing, motors that drive mixing or blending equipment are protected by overload relays to ensure reliable performance during long operational cycles.

Customization:TLY-A130T-HK64AA

-

Motor Protection in Industrial Equipment

- Conveyor Systems: Thermal overload relays are used to protect motors driving conveyor belts in manufacturing, packaging, and distribution facilities. These systems can experience varying loads, and the relay ensures that the motor does not overheat under excessive load conditions.

- Pumps: Motors driving pumps (e.g., water pumps, chemical pumps, fuel pumps) are protected from overheating and thermal damage, which can occur if the pump experiences a blockage or runs dry for an extended period.

- Compressors: Protects the motors in compressors (air compressors, refrigeration compressors) from damage due to prolonged overloading or abnormal conditions. Overload relays are essential in environments with frequent motor starts and stops.

- Fans and Blowers: Overload protection is crucial for motors in fans and blowers, which are common in industrial ventilation systems, HVAC units, and air handling equipment. Protecting these motors ensures long-term, reliable performance.

10. Construction and Infrastructure

Construction Machinery: Motors driving equipment like excavators, loaders, and other heavy construction machinery are protected by thermal overload relays to ensure the motors are not damaged by sustained overloads or operational anomalies.

Industrial Lifting Equipment: Overload relays protect motors in lifting equipment such as winches and cranes that are used in infrastructure projects, preventing motor damage from excessive lifting loads.

9. Renewable Energy Systems

Wind Turbines: Overload relays protect the motors in wind turbines that drive generators and other mechanical components, preventing damage from overloads during high winds or irregular operation conditions.

Solar Pumping Systems: In off-grid solar-powered pumping systems, the relay protects motors from overheating or overloading when the pump experiences sudden changes in load.

8. Automotive and Robotics Applications

Automated Systems: In automotive manufacturing and robotic systems, where motors are used to drive assembly lines or robotic arms, thermal overload relays help protect against potential failures due to excessive load conditions or system faults.

Electric Vehicles (EVs): Motors in electric vehicles or electric transportation systems (such as elevators in EV charging stations) may also use thermal overload relays for motor protection.

7. Elevators and Escalators

Elevators: Motors in elevator systems use thermal overload relays to protect against overheating caused by mechanical issues or overloads (e.g., if the elevator is carrying excessive weight).

Escalators: Overload protection is also used in escalators, ensuring that the motors driving the steps are not damaged by sustained or unexpected overcurrent conditions.

6. Agriculture and Food Processing

Farm Equipment: Motors in agricultural machinery such as grain elevators, mixers, and feed mills are protected by overload relays. These systems often work continuously, and overload protection helps prevent failures.

Food Processing: In food production lines, motors driving mixing, grinding, and packaging equipment are protected against overloads, ensuring consistent operation and avoiding expensive downtime.

5. Mining and Heavy Industry

Mining Equipment: In mining operations, motors that drive conveyors, crushers, and drilling equipment are subject to high and often unpredictable loads. Overload relays help protect these motors from damage caused by such extreme conditions.

Cranes and Hoists: Overload relays are used in large motors that drive cranes, hoists, and winches, where safety and protection are paramount in preventing motor damage or failure during lifting operations.

4. Manufacturing and Production Lines

Machine Tools: Thermal overload protection is critical for motors powering equipment such as CNC machines, lathes, drills, and other machine tools, which are exposed to varying loads during operation.

Material Handling: Conveyors, robotic arms, and other automated material handling equipment often use motors that benefit from overload protection to avoid motor failure during extended operations or heavy load conditions.

3. Water and Wastewater Systems

Water Treatment Plants: Motors that drive equipment such as water pumps, mixers, and agitators are protected from thermal damage in water treatment facilities.

Wastewater Pumps: Protects the motors used in wastewater pumping systems, which can face varying loads or resistance that could lead to an overload situation.

Irrigation Systems: Overload relays ensure motors in agricultural irrigation systems are protected against overloads caused by changes in water pressure, dry running, or system blockages.

2. HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC): In commercial or industrial HVAC systems, motors driving compressors, fans, or pumps benefit from protection by overload relays. These systems may experience frequent cycling, which increases the risk of overheating due to fluctuating loads.

Support and Services:TLY-A130T-HK64AA

Our Industrial Servo Drives product comes with comprehensive technical support and services to ensure optimal performance and reliability. Our team of experienced engineers are available for phone and email support to troubleshoot any issues you may encounter. We also offer on-site support for installation and commissioning, as well as training programs for your staff to ensure they have the knowledge and skills to properly operate and maintain the product.

In addition, we offer repair and maintenance services for our Industrial Servo Drives product to minimize downtime and keep your operations running smoothly. Our repair services include diagnostics, testing, and replacement of any faulty components. We also offer preventative maintenance services to help identify and address potential issues before they become major problems.

Our goal is to provide our customers with the highest level of support and service possible, and we are committed to ensuring your satisfaction with our Industrial Servo Drives product.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!