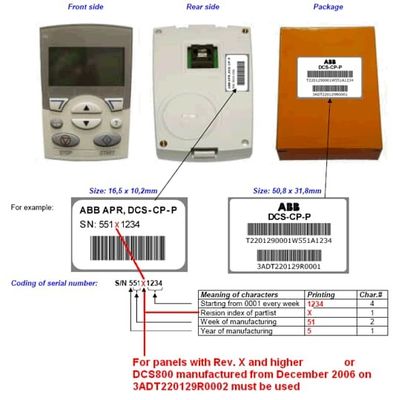

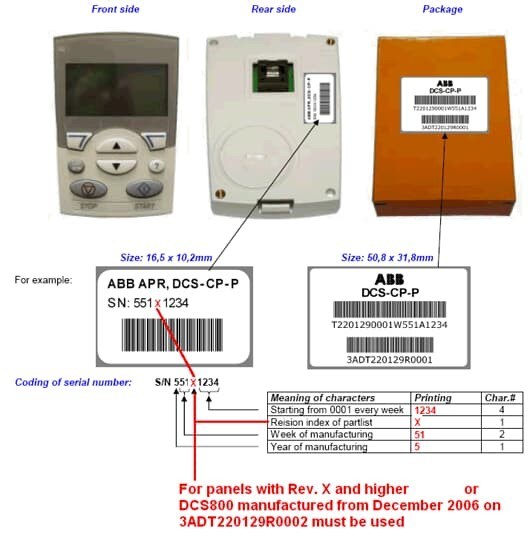

Product Description:3ADT220129R1001

- Overcurrent Protection: Protects against excess current flow that could cause overheating or damage to electrical components.

- Thermal Protection: Protects equipment like motors and transformers from overheating.

- Overvoltage and Undervoltage Protection: Prevents damage from voltage spikes or sags that could affect sensitive equipment.

- Short-circuit Protection: Instantly disconnects the circuit when a short-circuit condition is detected.

- Differential Protection: Provides high-speed protection for critical equipment like transformers or generators by comparing input and output currents.

- Earth Fault Protection: Detects leakage currents to ground, helping prevent electrical shock hazards or equipment damage.

-

Control and Automation:

- The relay likely features control functions for managing electrical networks, allowing remote or automated control actions such as tripping circuits in case of faults or resetting protection settings for system recovery.

- It may also include functions for load shedding, automatic reclosing, or sequence control depending on the network setup and operational needs.

-

Communication Capabilities:

- The 3ADT220129R1001 is probably equipped with advanced communication protocols for seamless integration into modern electrical systems:

- IEC 61850: A widely adopted protocol for substation automation, enabling communication between different protection and control devices in a substation or grid.

- Modbus RTU/TCP: For integration with SCADA (Supervisory Control and Data Acquisition) systems or other automation platforms.

- DNP3 and IEC 60870-5: Commonly used for remote monitoring and control in utility networks.

- These protocols allow the relay to communicate fault information, operational status, and diagnostic data to central monitoring stations for better visibility and faster response times.

-

Monitoring and Diagnostics:

- The relay likely includes self-diagnostic features to ensure the internal health of the relay itself, detecting any internal faults or issues that could compromise its performance.

- Event logging and fault recording functions store detailed logs of fault events, including time-stamped records of trips and protection actions, helping operators analyze faults and optimize system maintenance.

- Real-time system monitoring capabilities enable operators to observe voltage, current, and frequency conditions, providing comprehensive insights into the performance of the electrical network.

-

Customization and Configurability:

- Protection settings, such as trip thresholds, time delays, and current levels, are likely adjustable to suit different network configurations and applications.

- The relay can be configured with multiple protection groups to tailor the protection strategy to the operational requirements of various equipment or sections of the network.

-

Physical Design and Mounting:

- The 3ADT220129R1001 relay is typically designed for panel mounting or rack mounting for ease of integration into electrical cabinets, control panels, or switchgear.

- It is compact in size, ensuring that it fits in standard electrical panels without occupying excessive space.

-

Reliability and Safety:

- ABB relays are built to meet high standards of reliability, ensuring that protection and control functions operate accurately and consistently, even under challenging environmental conditions.

- The relay may be equipped with fault-tolerant features like redundant power supplies or alarm notifications to ensure continuous protection in case of power or communication failures.

Features:3ADT220129R1001

- Overcurrent Protection: Detects when current exceeds preset thresholds to protect against short circuits and overloads.

- Earth Fault Protection: Monitors for leakage currents to earth, ensuring that earth faults are detected promptly.

- Differential Protection: Detects internal faults in equipment like transformers, motors, and generators by comparing input and output currents.

- Overvoltage and Undervoltage Protection: Prevents damage to sensitive equipment from voltage fluctuations outside preset limits.

- Short-Circuit Protection: Provides fast protection against short circuits, minimizing equipment damage and system downtime.

- Thermal Overload Protection: Protects equipment from damage due to overheating, such as motor overload or transformer overheating.

-

2. Advanced Communication Protocols

The relay is designed to integrate seamlessly with modern substation and automation systems, featuring advanced communication capabilities:

- IEC 61850: A standard protocol for substation automation, enabling real-time communication between protection devices, control systems, and SCADA systems.

- Modbus RTU/TCP: A widely used communication protocol that allows for easy integration with SCADA or automation systems.

- DNP3 and IEC 60870-5: Additional protocols for remote monitoring and control, commonly used in utility networks.

-

These protocols ensure the relay can communicate fault information, status updates, and operational data to a central monitoring station, allowing for remote diagnostics, control, and monitoring.

3. Real-Time Monitoring and Diagnostics

- Self-Diagnostics: The relay performs continuous internal diagnostics to monitor its health and operational state, ensuring reliable protection.

- Fault Event Logging: Stores detailed records of fault events, including time-stamped information, enabling operators to analyze fault conditions and make data-driven decisions.

- Status Monitoring: Constantly monitors current, voltage, and frequency to provide insights into system conditions and detect any abnormal behavior.

-

4. Customizable Protection Settings

- Adjustable Protection Settings: Users can configure pickup thresholds, time delays, and other parameters to match the characteristics of the network or equipment being protected.

- Multiple Settings Groups: The relay allows for the configuration of different protection settings for different operational scenarios (e.g., normal operation, startup, maintenance), ensuring flexibility in a variety of operating conditions.

-

5. High-Speed Fault Detection and Tripping

- The 3ADT220129R1001 provides fast response times for fault detection and tripping to minimize damage to electrical equipment.

- It can provide instantaneous tripping for faults like short circuits, while also supporting time-delayed tripping for other conditions (e.g., overloads or earth faults), depending on the user’s configuration.

-

6. Event Logging and Fault Recordings

- Event Storage: The relay stores information about fault events, including the time of occurrence, trip actions, and protection settings. This data is useful for troubleshooting and ensuring proper system maintenance.

- Fault Recording: The relay can log the magnitude of faults, fault location (if supported by the system), and the protection action taken (trip or alarm).

-

7. Local and Remote Control

- Local Control: The relay can be operated locally via front-panel controls for functions like trip/reset, alarm silencing, and accessing protection settings.

- Remote Control: Allows for remote trip or reset commands via communication protocols, enabling operators to manage the system from a central control station or remote location.

-

8. Flexible I/O Options

- Digital Inputs/Outputs: Configurable digital inputs (e.g., for external status signals or alarms) and digital outputs (e.g., for triggering external relays or alarms) provide flexibility in integrating with other control devices.

- Analog Inputs: Depending on the model, the relay may offer analog inputs for measuring values like current or voltage for more precise fault detection and system monitoring.

-

9. Compact and Modular Design

- The relay is designed to be compact and easily integrated into existing electrical systems, typically mounted in standard panel or rack configurations.

- It is modular, allowing for scalability based on the needs of the system, including options for additional I/O or communication ports.

-

10. Enhanced Security and Cyber Protection

- Password Protection: Ensures that only authorized personnel can modify the relay’s configuration or access sensitive data.

- Encryption: For communication channels, encryption (e.g., TLS/SSL) may be available to secure data transmission, especially in sensitive utility or industrial environments.

- Access Control: The relay supports customizable access levels for different users, allowing operators to define roles and permissions for system access.

-

11. Environmental Durability

- The relay is designed to withstand a range of environmental conditions, including temperature variations, humidity, and vibration, ensuring reliability in harsh industrial environments.

- It typically comes with IP54 or higher ingress protection ratings, making it suitable for installation in panels that may be exposed to dust, moisture, or other challenging environmental factors.

-

12. Time Synchronization and Coordination

- The relay can synchronize with network time protocols (NTP) or utilize GPS synchronization for accurate time-stamping of event logs and fault recordings.

- This feature is crucial for coordinated protection, ensuring that fault detection and isolation occur in the correct sequence to avoid cascading failures in the system.

-

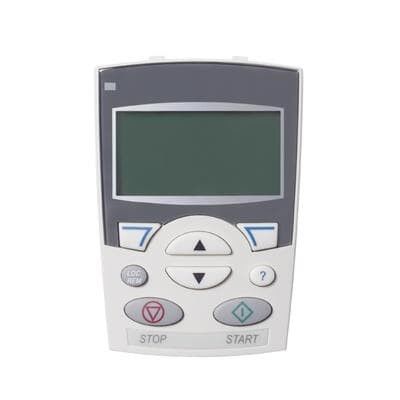

13. User-Friendly Interface and Configuration

- The relay is likely equipped with a local display (e.g., an LCD or LED panel) for status indication, event logs, and real-time system monitoring.

- It may also support user-friendly software tools for configuration, allowing operators to program protection settings, view diagnostic data, and generate reports easily.

- Graphical interfaces may be available for easier visualization of protection settings, fault events, and system performance.

Technical Parameters:3ADT220129R1001

| Nominal Voltage (AC/DC) |

100-240 V AC/DC |

| Rated Current (In) |

1–100 A (adjustable) |

| Overcurrent Protection |

Instantaneous and time-delayed |

| Earth Fault Protection |

Residual current detection |

| Differential Protection |

Yes (for transformers, generators) |

| Overload Protection |

Adjustable time delay |

| Relay Outputs |

4–8 outputs (NO/NC) |

| Communication Protocols |

IEC 61850, Modbus RTU/TCP, DNP3 |

| Accuracy |

±1% for current and voltage |

| Operating Temp Range |

-20°C to +60°C |

| Ingress Protection |

IP54 or higher |

| Dimensions |

Compact (typical panel-mount) |

| Event Logging |

100–500 events |

|

Applications:3ADT220129R1001

- Medium-Voltage Distribution Protection: The relay is used in medium-voltage distribution systems to protect power lines, feeders, transformers, and other critical components from faults such as short circuits, overcurrent, and earth faults.

- Feeder Protection: It provides protection for electrical feeders by detecting faults like overloads, short circuits, and earth faults, ensuring the continuous supply of power to downstream loads.

- Substation Automation Systems: The ABB 3ADT220129R1001 relay is integral in substation automation, enabling intelligent fault detection, real-time monitoring, and remote control through communication protocols like IEC 61850, Modbus RTU/TCP, and DNP3.

- Transformer Protection: It protects transformers from a variety of faults, including internal faults (through differential protection), overloads, and external faults (via overcurrent and earth fault protection).

- Switchgear Protection: Provides protection for switchgear in substations, ensuring that any abnormal conditions (such as overcurrent or earth faults) result in swift tripping, preventing damage to the equipment.

- Motor Protection: The relay offers protection for motors, which are critical components in industrial processes. It safeguards motors from faults like overload, short circuits, earth faults, and thermal overloads.

- Generator Protection: Protects generators from issues such as overvoltage, undervoltage, overcurrent, reverse power flow, and differential faults.

- Industrial Automation: The relay is often integrated into industrial control and automation systems for load shedding, start/stop sequences, and remote monitoring of industrial electrical systems.

- Solar Power Plants: The relay can be used to protect electrical components within solar power plants, such as inverters, transformers, and distribution lines, from faults and abnormal conditions.

- Wind Farms: For wind turbine power systems, the relay ensures that turbines and associated electrical equipment are protected from issues like overcurrent, earth faults, and overvoltage.

- Energy Storage Systems: In battery storage systems, the relay can protect against faults like overcharging, overdischarging, and internal battery faults.

- Grid Protection and Monitoring: The relay is crucial in smart grid applications, where it provides grid protection, fault isolation, and control functions in the event of abnormal conditions like power surges, dips, or fault propagation across the grid.

- Load Shedding and Demand Response: It can help optimize grid performance by enabling load shedding during peak demand periods or in response to network disturbances.

- Commercial Power Distribution: The relay is used to protect electrical equipment in commercial buildings like offices, malls, hospitals, and hotels. It ensures that electrical distribution systems remain operational and protect against faults, minimizing downtime and preventing damage to critical infrastructure.

- Critical Load Protection: In facilities where continuous power is essential (e.g., data centers, hospitals, and telecom towers), the relay helps prevent power interruptions by protecting key equipment from faults that could disrupt service.

- Mining Operations: Mining operations require heavy-duty electrical systems that are subject to high loads and frequent changes in operational conditions. The relay provides fault protection, overcurrent protection, and ground fault detection for mining equipment and electrical networks.

- Heavy Industrial Equipment: The relay is used to protect transformers, motors, generators, and other critical equipment in heavy industries such as steel, cement, and chemical plants. It ensures that machinery continues to operate safely even under demanding conditions.

- Marine Power Systems: On ships and offshore platforms, the relay can be used to protect electrical distribution systems, generators, and motors from faults caused by harsh environments, vibration, and other challenging operational conditions.

- Offshore Oil and Gas Platforms: It protects the critical electrical infrastructure on offshore platforms, ensuring continuous operation of safety systems, lighting, and other vital electrical systems.

- Data Center Protection: In data centers, the relay protects power supplies to servers, UPS (uninterruptible power supplies), and cooling systems. Protection from faults such as overvoltage, undervoltage, and overload ensures that servers stay operational.

- Telecom Stations: Protects the electrical systems of telecom towers and communication infrastructure, ensuring minimal downtime for network operation.

- EV Charging Station Protection: As the popularity of electric vehicles increases, the relay can be used in charging stations to protect the charging equipment and ensure that electrical faults do not cause damage to the infrastructure or vehicles.

Customization:3ADT220129R1001

The 3ADT220129R1001 supports multiple communication protocols for integration into modern control and monitoring systems, and these can be customized for your specific communication needs.

-

IEC 61850:

- Communication Integration: The relay can be customized for seamless integration into a substation automation system using IEC 61850. It can communicate with other devices in the substation for real-time monitoring, control, and fault detection. The relay can be configured to share or receive data on status, measurements, and alarms via GOOSE messages (Generic Object Oriented Substation Event) or MMS (Manufacturing Message Specification).

- Logical Node Customization: You can configure logical nodes for specific protection or control functions, as well as manage settings and data exchange via XML configuration files.

-

Modbus RTU/TCP:

- The relay supports Modbus RTU (over RS-485) and Modbus TCP (over Ethernet). You can configure these protocols to integrate the relay with SCADA systems, PLC controllers, or supervisory systems for remote monitoring and control.

-

DNP3:

- For remote monitoring in utility networks, the relay can be customized to support DNP3 (Distributed Network Protocol) for secure and reliable communication with utility SCADA systems.

-

Other Protocols:

- Depending on the version and model of the relay, other communication protocols such as IEC 60870-5-104, Profibus, or Ethernet/IP may also be supported. These options can be customized based on the user’s needs for remote access and system integration.

-

Data Logging & Alarms:

- You can customize how the relay logs events, faults, and alarms, with configurable time stamps and data storage capacities.

- Alarms and notifications can be customized to trigger actions (such as trip signals, external alarms, or remote communication) when specific protection thresholds are exceeded.

Support and Services:3ADT220129R1001

Our Industrial Servo Drives are designed to ensure that your machinery operates with precision and reliability. We offer a range of technical support and services to help you get the most out of your servo drives.

We provide product documentation, including user manuals and datasheets, to help you understand the features and capabilities of our servo drives. Our technical experts are available to provide guidance on installation, configuration, and troubleshooting to ensure that your machinery is up and running quickly.

In addition, we offer training services to help you and your team develop the skills needed to operate and maintain your servo drives. Our training programs cover a range of topics, from basic servo drive operation to advanced programming and maintenance.

Finally, we offer repair and maintenance services to help you keep your machinery running smoothly. Our experienced technicians can diagnose and repair issues with your servo drives, and we offer preventative maintenance services to keep your drives operating at peak performance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!